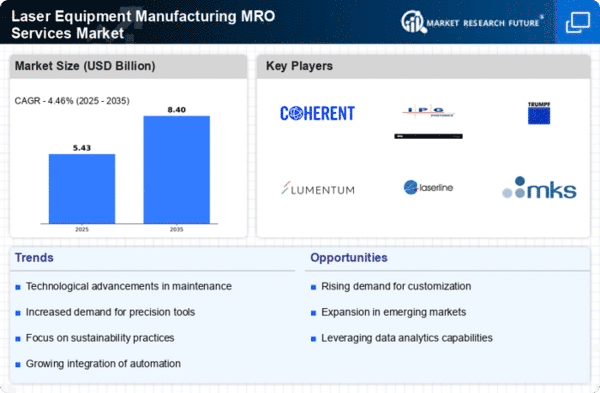

The Laser Equipment Manufacturing MRO Services Market is characterized by a dynamic competitive landscape, driven by technological advancements and increasing demand for precision manufacturing across various sectors. Key players such as Coherent Inc (US), IPG Photonics Corporation (US), and TRUMPF GmbH + Co. KG (DE) are at the forefront, each adopting distinct strategies to enhance their market positioning. Coherent Inc (US) focuses on innovation through significant investments in R&D, aiming to develop cutting-edge laser technologies that cater to diverse applications. Meanwhile, IPG Photonics Corporation (US) emphasizes regional expansion, particularly in Asia, to capitalize on the growing demand for laser solutions in manufacturing processes. TRUMPF GmbH + Co. KG (DE) is actively pursuing digital transformation initiatives, integrating smart technologies into their product offerings to improve operational efficiency and customer engagement.The market structure appears moderately fragmented, with a mix of established players and emerging companies vying for market share. Key business tactics such as localizing manufacturing and optimizing supply chains are prevalent among these companies, allowing them to respond swiftly to market demands and enhance service delivery. The collective influence of these major players shapes the competitive environment, fostering an ecosystem where innovation and operational excellence are paramount.

In November Coherent Inc (US) announced a strategic partnership with a leading semiconductor manufacturer to develop advanced laser systems tailored for the semiconductor industry. This collaboration is poised to enhance Coherent's product portfolio and strengthen its foothold in a rapidly evolving market, where precision and efficiency are critical. The partnership underscores the importance of aligning with industry leaders to drive innovation and meet specific customer needs.

In October IPG Photonics Corporation (US) unveiled a new line of high-power fiber lasers designed for industrial applications, showcasing their commitment to innovation. This product launch not only reinforces IPG's position as a technology leader but also addresses the increasing demand for energy-efficient solutions in manufacturing. The introduction of these lasers is likely to attract new customers and expand their market reach.

In September TRUMPF GmbH + Co. KG (DE) completed the acquisition of a software company specializing in AI-driven manufacturing solutions. This strategic move is expected to enhance TRUMPF's capabilities in smart manufacturing, allowing them to offer integrated solutions that combine hardware and software. The acquisition reflects a broader trend in the industry towards the integration of AI and automation, which is becoming increasingly vital for maintaining competitive advantage.

As of December current trends in the Laser Equipment Manufacturing MRO Services Market indicate a strong emphasis on digitalization, sustainability, and AI integration. Strategic alliances are increasingly shaping the competitive landscape, enabling companies to leverage complementary strengths and enhance their offerings. Looking ahead, competitive differentiation is likely to evolve from traditional price-based competition to a focus on innovation, technological advancements, and supply chain reliability. This shift suggests that companies that prioritize R&D and strategic partnerships will be better positioned to thrive in an increasingly complex market.