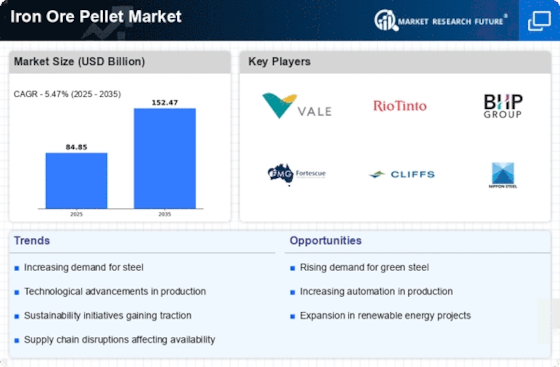

Rising Steel Production Demand

The Iron Ore Pellet Market is experiencing a surge in demand driven by the increasing production of steel. As economies expand, the need for steel in construction, automotive, and infrastructure projects rises. In 2025, steel production is projected to reach approximately 1.9 billion tons, with a significant portion derived from iron ore pellets due to their high iron content and efficiency in the steelmaking process. This trend suggests that the Iron Ore Pellet Market will continue to thrive as steel manufacturers seek to optimize their production processes and reduce emissions, aligning with sustainability goals. Furthermore, the shift towards electric arc furnaces, which utilize iron ore pellets more effectively, may further bolster demand in the coming years.

Environmental Regulations and Compliance

The Iron Ore Pellet Market is increasingly influenced by stringent environmental regulations aimed at reducing carbon emissions and promoting sustainable practices. Governments worldwide are implementing policies that encourage the use of cleaner technologies in steel production. As a result, steelmakers are turning to iron ore pellets, which produce lower emissions compared to traditional sinter. In 2025, it is estimated that around 60% of new steel production facilities will adopt pellet-based processes to comply with these regulations. This shift not only enhances the market for iron ore pellets but also positions the Iron Ore Pellet Market as a key player in the transition towards greener steel production methods.

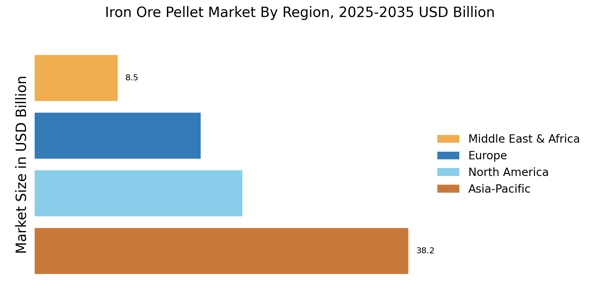

Increasing Investment in Mining Operations

The Iron Ore Pellet Market is benefiting from rising investments in mining operations, particularly in regions rich in iron ore deposits. As demand for iron ore pellets grows, mining companies are expanding their operations to increase production capacity. In 2025, investments in mining are projected to exceed $100 billion, with a significant portion allocated to enhancing pellet production facilities. This influx of capital is likely to improve the supply chain dynamics within the Iron Ore Pellet Market, ensuring that producers can meet the escalating demand from steel manufacturers. Additionally, these investments may lead to the adoption of more sustainable mining practices, further enhancing the industry's reputation.

Technological Innovations in Pellet Production

Technological advancements in the Iron Ore Pellet Market are reshaping production processes, enhancing efficiency and product quality. Innovations such as the development of direct reduction iron (DRI) technology and improvements in pelletizing techniques are enabling producers to create higher-grade pellets with lower impurities. In 2025, the market is expected to witness a 15% increase in the adoption of advanced pelletizing technologies, which could lead to a more competitive landscape. These innovations not only improve the economic viability of iron ore pellets but also align with the industry's focus on sustainability, as they often require less energy and water compared to traditional methods.

Global Economic Recovery and Infrastructure Development

The Iron Ore Pellet Market is poised to benefit from the ongoing economic recovery and infrastructure development initiatives across various regions. As countries invest in rebuilding and expanding their infrastructure, the demand for steel, and consequently iron ore pellets, is expected to rise. In 2025, infrastructure spending is anticipated to reach $4 trillion, with a substantial portion directed towards projects that require high-quality steel. This trend indicates a robust growth trajectory for the Iron Ore Pellet Market, as steel producers seek reliable sources of iron ore pellets to meet the increasing demand. Furthermore, the focus on sustainable infrastructure may further enhance the appeal of iron ore pellets, given their environmental advantages.