Advancements in Sensor Technology

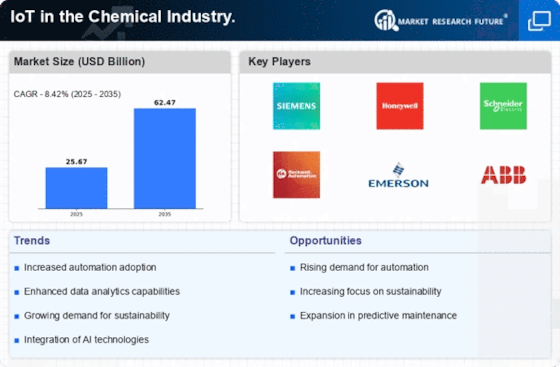

Advancements in sensor technology are playing a pivotal role in the growth of the IoT In Chemical Industry Market. The development of more sophisticated and cost-effective sensors enables chemical manufacturers to gather accurate data on various parameters such as temperature, pressure, and chemical composition. These sensors can be integrated into IoT platforms, allowing for seamless data transmission and analysis. The market for industrial sensors is projected to grow significantly, with estimates suggesting a compound annual growth rate of over 10% in the coming years. This technological evolution not only enhances operational efficiency but also supports predictive maintenance strategies, reducing the likelihood of equipment failures. As sensor technology continues to advance, its impact on the IoT In Chemical Industry Market will likely be profound.

Integration of Artificial Intelligence

The integration of artificial intelligence (AI) with IoT technologies is emerging as a transformative driver in the IoT In Chemical Industry Market. AI algorithms can analyze vast amounts of data generated by IoT devices, providing insights that lead to improved decision-making and operational efficiency. For instance, predictive analytics can forecast equipment failures, allowing for timely maintenance and reducing downtime. The potential for AI to optimize production processes is substantial, with studies indicating that AI-driven solutions can enhance productivity by up to 20%. As chemical companies seek to leverage data for competitive advantage, the convergence of AI and IoT is expected to accelerate, further propelling the growth of the IoT In Chemical Industry Market.

Increased Demand for Real-Time Monitoring

The IoT In Chemical Industry Market is experiencing a surge in demand for real-time monitoring solutions. This trend is driven by the need for enhanced operational efficiency and safety in chemical production processes. Companies are increasingly adopting IoT technologies to monitor equipment performance, track inventory levels, and ensure compliance with safety regulations. According to recent data, the implementation of IoT solutions can reduce operational costs by up to 30%, making it a financially attractive option for chemical manufacturers. Furthermore, real-time data analytics allows for proactive decision-making, minimizing downtime and optimizing resource allocation. As the industry continues to evolve, the integration of IoT technologies is likely to become a standard practice, further propelling the growth of the IoT In Chemical Industry Market.

Regulatory Compliance and Safety Standards

The IoT In Chemical Industry Market is significantly influenced by stringent regulatory compliance and safety standards. Governments and regulatory bodies are increasingly mandating the use of advanced technologies to ensure safety in chemical handling and production. IoT solutions facilitate compliance by providing real-time data on emissions, chemical usage, and safety incidents. This capability not only helps companies adhere to regulations but also enhances their reputation in the market. The potential for IoT technologies to improve safety outcomes is substantial, as they can detect anomalies and alert personnel before incidents occur. As regulations become more rigorous, the adoption of IoT solutions in the chemical sector is expected to rise, thereby driving growth in the IoT In Chemical Industry Market.

Focus on Sustainability and Environmental Impact

The growing focus on sustainability and reducing environmental impact is a key driver in the IoT In Chemical Industry Market. Companies are increasingly adopting IoT solutions to monitor and manage their environmental footprint, including emissions and waste management. IoT technologies enable real-time tracking of environmental parameters, facilitating compliance with sustainability goals and regulations. The market for green chemicals is also expanding, with projections indicating a growth rate of over 15% in the next few years. By leveraging IoT solutions, chemical manufacturers can optimize resource usage and minimize waste, aligning their operations with global sustainability initiatives. This shift towards environmentally responsible practices is likely to enhance the appeal of the IoT In Chemical Industry Market.