Growth in Chemical Processing

The Industrial Spray Valves Market is significantly benefiting from the growth in the chemical processing sector. As the global chemical industry continues to expand, the demand for efficient spray systems for mixing, coating, and application processes is on the rise. In 2025, the chemical processing industry is expected to witness a growth rate of around 3.8%, which is likely to drive the adoption of advanced spray valves. These valves play a crucial role in ensuring uniform distribution and optimal performance of chemicals, thereby enhancing operational efficiency. Furthermore, the increasing complexity of chemical formulations necessitates the use of specialized spray valves, suggesting a promising outlook for the Industrial Spray Valves Market in this sector.

Emergence of Eco-Friendly Solutions

The Industrial Spray Valves Market is increasingly influenced by the emergence of eco-friendly solutions. As industries strive to reduce their environmental footprint, there is a growing emphasis on sustainable practices, including the use of low-VOC and water-based coatings. This shift is prompting manufacturers to invest in advanced spray valve technologies that facilitate the application of these environmentally friendly materials. In 2025, the market for eco-friendly coatings is projected to grow at a CAGR of 5.2%, which is likely to bolster the demand for compatible spray valves. The alignment of industrial spray valves with sustainability goals not only enhances their market appeal but also positions the Industrial Spray Valves Market favorably in a competitive landscape.

Increasing Focus on Safety Standards

The Industrial Spray Valves Market is increasingly shaped by the rising focus on safety standards across various sectors. As industries prioritize worker safety and compliance with stringent regulations, the demand for reliable and safe spray valve solutions is on the rise. In 2025, the implementation of new safety regulations is expected to drive the adoption of advanced spray valves that meet these standards. Manufacturers are compelled to invest in high-quality, durable valves that ensure safe operation under various conditions. This heightened emphasis on safety not only enhances the credibility of the Industrial Spray Valves Market but also fosters innovation in valve design and functionality.

Rising Demand in Manufacturing Sector

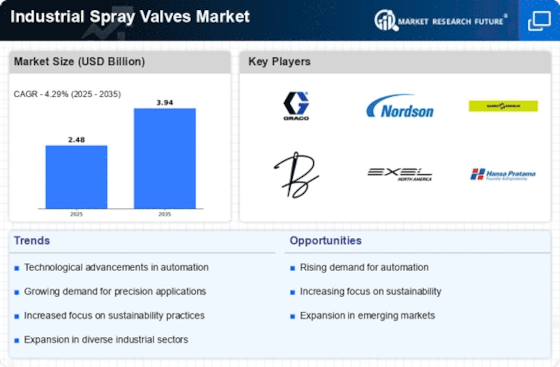

The Industrial Spray Valves Market is experiencing a notable surge in demand, primarily driven by the expansion of the manufacturing sector. As industries increasingly adopt automation and advanced manufacturing techniques, the need for efficient and precise spray applications becomes paramount. In 2025, the manufacturing sector is projected to grow at a compound annual growth rate (CAGR) of approximately 4.5%, which directly influences the demand for industrial spray valves. These valves are essential for various applications, including coating, painting, and surface treatment, thereby enhancing productivity and quality. The integration of smart technologies in manufacturing processes further amplifies the need for sophisticated spray valve solutions, indicating a robust growth trajectory for the Industrial Spray Valves Market.

Technological Innovations in Spray Systems

The Industrial Spray Valves Market is witnessing a wave of technological innovations that are reshaping the landscape of spray systems. Advancements in automation, precision engineering, and control systems are leading to the development of highly efficient spray valves. These innovations enable manufacturers to achieve greater accuracy and consistency in their applications, which is crucial for maintaining product quality. In 2025, the market for automated spray systems is anticipated to grow significantly, driven by the need for enhanced operational efficiency. The integration of IoT and smart technologies into spray valve systems further enhances their functionality, suggesting a transformative impact on the Industrial Spray Valves Market.