North America : Leading Market Innovators

North America is poised to maintain its leadership in the Industrial Robotics Maintenance and Repair Services Market, holding a market size of $4.0B in 2025. Key growth drivers include the rapid adoption of automation technologies, increased demand for efficiency, and supportive regulatory frameworks. The region's focus on innovation and investment in advanced robotics technologies further fuels market expansion, with a projected growth rate of 8% annually.

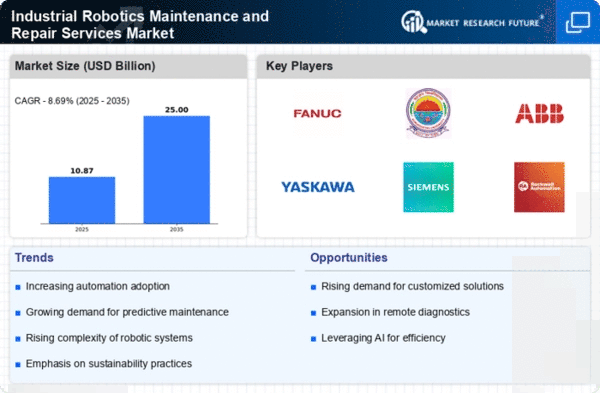

The competitive landscape is characterized by major players such as Rockwell Automation, Siemens, and ABB, which are driving advancements in robotics maintenance. The U.S. leads the market, supported by a robust manufacturing sector and significant investments in R&D. Canada and Mexico are also emerging as key players, contributing to the region's overall growth and technological advancements.

Europe : Innovation and Sustainability Focus

Europe's Industrial Robotics Maintenance and Repair Services Market is projected to reach $3.0B by 2025, driven by a strong emphasis on innovation and sustainability. The region benefits from stringent regulations promoting automation and efficiency, which are key catalysts for market growth. Countries like Germany and France are at the forefront, with a growing demand for advanced robotics solutions in manufacturing and logistics sectors, leading to an annual growth rate of 7%.

Germany stands out as a leader in robotics technology, hosting major players like KUKA and Siemens. The competitive landscape is further enhanced by collaborations between industry and academia, fostering innovation. The European market is characterized by a diverse range of service providers, ensuring a comprehensive approach to maintenance and repair services, which is crucial for sustaining operational efficiency.

Asia-Pacific : Emerging Market Potential

The Asia-Pacific region is witnessing significant growth in the Industrial Robotics Maintenance and Repair Services Market, projected to reach $2.5B by 2025. Key drivers include the rapid industrialization in countries like China and India, coupled with increasing investments in automation technologies. The region's market is expected to grow at a rate of 6% annually, fueled by rising labor costs and the need for operational efficiency.

China is the dominant player in the market, with substantial investments in robotics and automation. Japan and South Korea also contribute significantly, with established companies like Fanuc and Yaskawa leading the charge. The competitive landscape is evolving, with new entrants focusing on innovative maintenance solutions, enhancing service delivery and operational uptime across various industries.

Middle East and Africa : Untapped Market Opportunities

The Middle East and Africa region is gradually emerging in the Industrial Robotics Maintenance and Repair Services Market, with a projected size of $0.5B by 2025. The growth is driven by increasing investments in automation and a shift towards advanced manufacturing practices. Countries like the UAE and South Africa are leading the charge, with government initiatives aimed at enhancing industrial capabilities and attracting foreign investments, resulting in a growth rate of 5% annually.

The competitive landscape is still developing, with a mix of local and international players entering the market. The presence of key players is limited, but there is a growing interest in robotics solutions across various sectors, including oil and gas, manufacturing, and logistics. As the region continues to invest in technology, the potential for growth in maintenance and repair services is significant.