Market Growth Projections

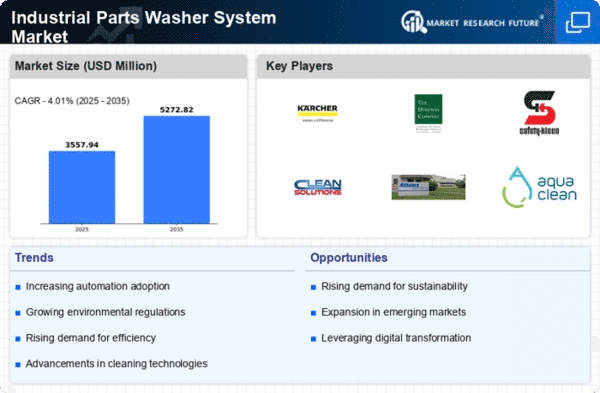

The Global Industrial Parts Washer System Market Industry is projected to experience substantial growth over the next decade. The market is expected to reach a valuation of 5.27 USD Billion by 2035, growing from 3.42 USD Billion in 2024. This growth trajectory reflects a compound annual growth rate (CAGR) of 4.02% from 2025 to 2035. Factors contributing to this growth include increasing industrialization, technological advancements, and a heightened emphasis on sustainability. As industries continue to evolve, the demand for efficient and environmentally friendly parts washer systems is likely to rise, driving innovation and investment in this sector.

Technological Advancements in Washer Systems

Technological advancements play a pivotal role in shaping the Global Industrial Parts Washer System Market Industry. Innovations such as automated cleaning processes, ultrasonic cleaning, and advanced filtration systems enhance the effectiveness of parts washers. These technologies not only improve cleaning efficiency but also reduce water and energy consumption, aligning with global sustainability goals. As industries increasingly adopt smart manufacturing practices, the integration of IoT and AI into parts washer systems is expected to rise. This trend could lead to a more streamlined operation, ultimately contributing to the projected market growth from 3.42 USD Billion in 2024 to 5.27 USD Billion by 2035.

Expansion of Manufacturing Activities Globally

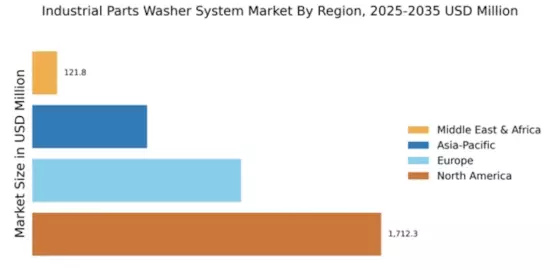

The expansion of manufacturing activities globally serves as a significant driver for the Global Industrial Parts Washer System Market Industry. As emerging economies ramp up production capabilities, the demand for industrial cleaning solutions rises correspondingly. Countries in Asia-Pacific and Latin America are witnessing increased investments in manufacturing infrastructure, leading to a heightened need for effective parts washing systems. This growth is anticipated to contribute to the market's expansion, with projections indicating a rise from 3.42 USD Billion in 2024 to 5.27 USD Billion by 2035. The global shift towards automation and efficiency in manufacturing processes further underscores the necessity for advanced parts washer systems.

Growing Demand for Efficient Cleaning Solutions

The Global Industrial Parts Washer System Market Industry experiences a growing demand for efficient cleaning solutions across various sectors, including automotive, aerospace, and manufacturing. As industries strive for enhanced productivity and reduced downtime, the adoption of advanced parts washer systems becomes crucial. These systems not only ensure thorough cleaning but also minimize environmental impact through the use of eco-friendly solvents. In 2024, the market is valued at 3.42 USD Billion, reflecting the increasing investment in technologies that improve operational efficiency. Companies are likely to prioritize systems that offer both performance and sustainability, indicating a shift towards greener practices in industrial cleaning.

Regulatory Compliance and Environmental Standards

Regulatory compliance and stringent environmental standards significantly influence the Global Industrial Parts Washer System Market Industry. Governments worldwide are implementing regulations aimed at reducing hazardous waste and promoting sustainable practices. As a result, industries are compelled to invest in parts washer systems that comply with these regulations. The need for environmentally friendly cleaning solutions drives the demand for advanced systems that utilize biodegradable solvents and minimize water usage. This trend is likely to accelerate market growth, as companies seek to avoid penalties and enhance their corporate responsibility. The anticipated CAGR of 4.02% from 2025 to 2035 underscores the importance of compliance in shaping market dynamics.

Rising Focus on Maintenance and Equipment Longevity

The rising focus on maintenance and equipment longevity is a key driver in the Global Industrial Parts Washer System Market Industry. Industries recognize that regular cleaning and maintenance of machinery and components are essential for optimal performance and longevity. Parts washer systems facilitate this process by ensuring that equipment remains free from contaminants that could lead to wear and tear. As companies increasingly prioritize preventive maintenance strategies, the demand for reliable and efficient parts washer systems is expected to grow. This trend not only enhances operational efficiency but also contributes to cost savings, further solidifying the market's expansion in the coming years.