Focus on Cost Efficiency

Cost efficiency remains a critical factor influencing the Industrial Food Slicers Market. As food manufacturers and processors strive to optimize their operations, the demand for cost-effective slicing solutions is increasing. Companies are seeking equipment that not only reduces labor costs but also minimizes waste and energy consumption. Market data indicates that investments in energy-efficient slicers are expected to rise by 10% in the coming years, as businesses aim to enhance their bottom line. This focus on cost efficiency is driving innovation within the Industrial Food Slicers Market, as manufacturers develop products that align with the financial objectives of their clients.

Technological Innovations

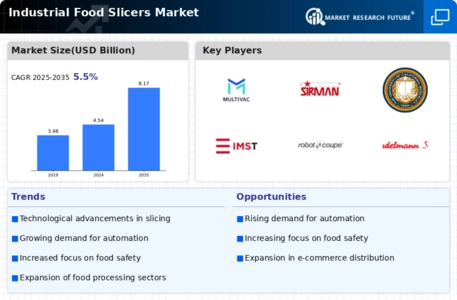

Technological advancements play a pivotal role in shaping the Industrial Food Slicers Market. Innovations such as automated slicing machines and smart technology integration are enhancing operational efficiency and precision in food processing. For instance, the introduction of machines equipped with artificial intelligence allows for real-time monitoring and adjustments, ensuring consistent product quality. Market data suggests that the adoption of such technologies is expected to increase by 20% in the next few years, as manufacturers strive to reduce labor costs and improve productivity. This trend indicates a shift towards more sophisticated slicing solutions, which are likely to dominate the Industrial Food Slicers Market in the near future.

Health and Safety Regulations

The stringent health and safety regulations imposed on food processing industries are significantly influencing the Industrial Food Slicers Market. Compliance with these regulations necessitates the use of high-quality, efficient slicing equipment that minimizes contamination risks. As food safety becomes a paramount concern, manufacturers are compelled to invest in advanced slicing technologies that adhere to regulatory standards. Market data reveals that the demand for hygienic and easy-to-clean slicers is on the rise, with a projected increase of 15% in sales over the next few years. This trend underscores the importance of safety in food processing, thereby driving growth in the Industrial Food Slicers Market.

Growth of the Food Service Sector

The expansion of the food service sector is a key driver for the Industrial Food Slicers Market. With the rise of restaurants, catering services, and food delivery businesses, there is an escalating need for efficient food preparation equipment. The food service industry is anticipated to grow at a rate of 5% annually, leading to increased investments in industrial food slicers to enhance operational efficiency. This growth is prompting food service operators to seek versatile slicing solutions that can accommodate a variety of food products. As a result, the Industrial Food Slicers Market is likely to benefit from this trend, as manufacturers develop products tailored to the specific needs of food service providers.

Rising Demand for Processed Foods

The increasing consumer preference for convenience foods is driving the Industrial Food Slicers Market. As lifestyles become busier, the demand for ready-to-eat and processed food products rises. This trend is reflected in market data, which indicates that the processed food sector is projected to grow at a compound annual growth rate of approximately 4.5% over the next five years. Consequently, food manufacturers are investing in advanced slicing technologies to enhance production efficiency and meet consumer expectations. The Industrial Food Slicers Market is thus experiencing a surge in demand as manufacturers seek to optimize their operations and deliver high-quality products that cater to the evolving tastes of consumers.