North America : Market Leader in CNC Services

North America continues to lead the Industrial CNC Repair and Overhaul Services Market, holding a significant market share of 3.25 billion. The growth is driven by a robust manufacturing sector, increasing automation, and a rising demand for precision engineering. Regulatory support for advanced manufacturing technologies further catalyzes this growth, ensuring compliance and safety standards are met.

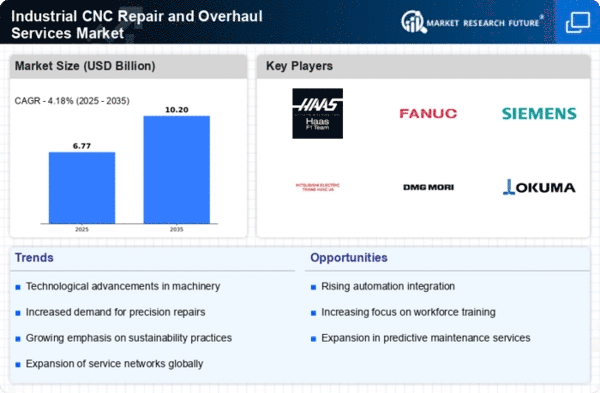

The United States stands out as the primary market, with key players like Haas Automation and Mazak Corporation driving innovation and service excellence. The competitive landscape is characterized by a mix of established firms and emerging players, all vying for market share. The focus on technological advancements and customer-centric solutions positions North America as a hub for CNC repair services.

Europe : Emerging CNC Repair Hub

Europe's Industrial CNC Repair and Overhaul Services Market is valued at 1.8 billion, reflecting a growing demand for high-quality manufacturing solutions. The region benefits from stringent regulations that promote safety and efficiency in manufacturing processes. Additionally, the push for sustainability and energy efficiency in industrial operations is driving investments in CNC technologies, enhancing service offerings.

Germany and the UK are leading countries in this sector, with major players like Siemens AG and DMG Mori establishing a strong presence. The competitive landscape is marked by innovation and collaboration among firms, focusing on advanced technologies and customer satisfaction. The European market is poised for growth as companies adapt to evolving industry standards and customer needs.

Asia-Pacific : Rapid Growth in CNC Services

The Asia-Pacific region, valued at 1.5 billion, is witnessing rapid growth in the Industrial CNC Repair and Overhaul Services Market. This growth is fueled by increasing industrialization, a surge in manufacturing activities, and a growing emphasis on automation. Countries in this region are investing heavily in modernizing their manufacturing capabilities, which is driving demand for CNC repair services.

Japan and China are at the forefront, with key players like FANUC Corporation and Mitsubishi Electric leading the market. The competitive landscape is dynamic, with both local and international firms competing for market share. As the region continues to embrace technological advancements, the CNC services market is expected to expand significantly, catering to diverse industrial needs.

Middle East and Africa : Emerging Market Potential

The Middle East and Africa region, with a market size of 0.95 billion, presents emerging opportunities in the Industrial CNC Repair and Overhaul Services Market. The growth is driven by increasing investments in manufacturing and infrastructure development, alongside a rising demand for advanced machining solutions. Regulatory frameworks are evolving to support industrial growth, enhancing the market's attractiveness.

Countries like South Africa and the UAE are leading the charge, with a growing number of local and international players entering the market. The competitive landscape is characterized by a focus on innovation and service quality, as firms strive to meet the unique demands of the region. As the market matures, opportunities for growth and collaboration are expected to increase significantly.