Stringent Regulatory Standards

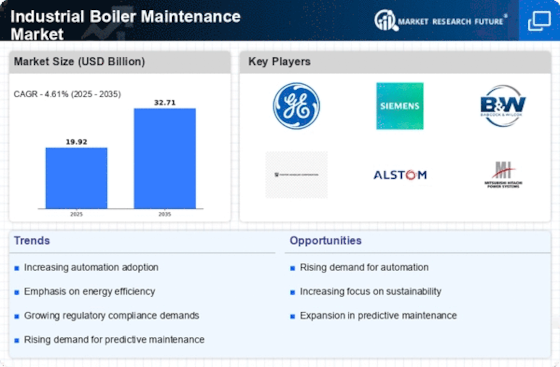

The Industrial Boiler Maintenance Market is significantly influenced by stringent regulatory standards aimed at ensuring safety and environmental protection. Governments and regulatory bodies are implementing rigorous guidelines that mandate regular inspections and maintenance of industrial boilers. Compliance with these regulations is essential for companies to avoid hefty fines and operational disruptions. For instance, the implementation of emissions standards has led to an increased focus on maintaining boiler efficiency to meet compliance requirements. As a result, the demand for maintenance services that ensure adherence to these regulations is expected to grow, thereby driving the Industrial Boiler Maintenance Market.

Rising Demand for Energy Efficiency

The Industrial Boiler Maintenance Market is experiencing a notable increase in demand for energy-efficient solutions. As industries strive to reduce operational costs and enhance productivity, the focus on maintaining boilers to operate at optimal efficiency becomes paramount. According to recent data, energy-efficient boilers can reduce fuel consumption by up to 15%, which translates into significant cost savings. This trend is further fueled by the growing awareness of energy conservation and the need to comply with environmental regulations. Consequently, companies are investing in regular maintenance services to ensure their boilers function efficiently, thereby driving growth in the Industrial Boiler Maintenance Market.

Technological Advancements in Maintenance Practices

Technological advancements are reshaping the Industrial Boiler Maintenance Market, introducing innovative maintenance practices that enhance efficiency and reliability. The integration of predictive maintenance technologies, such as IoT sensors and data analytics, allows for real-time monitoring of boiler performance. This proactive approach not only minimizes downtime but also extends the lifespan of equipment. Recent studies indicate that predictive maintenance can reduce maintenance costs by up to 30%. As industries increasingly adopt these technologies, the demand for specialized maintenance services is likely to rise, further propelling the growth of the Industrial Boiler Maintenance Market.

Focus on Sustainability and Environmental Responsibility

The growing emphasis on sustainability and environmental responsibility is a key driver in the Industrial Boiler Maintenance Market. Companies are increasingly recognizing the importance of reducing their carbon footprint and minimizing environmental impact. This shift is prompting industries to invest in the maintenance of boilers that utilize cleaner technologies and fuels. Furthermore, regular maintenance is essential to ensure that boilers operate within optimal emissions limits. As organizations strive to meet sustainability goals, the demand for maintenance services that support environmentally friendly practices is likely to increase, thereby influencing the Industrial Boiler Maintenance Market.

Increasing Industrial Production and Infrastructure Development

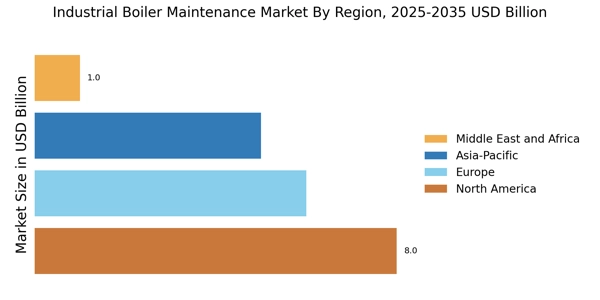

The Industrial Boiler Maintenance Market is poised for growth due to the increasing industrial production and infrastructure development across various sectors. As manufacturing and construction activities expand, the demand for reliable steam and heating solutions rises, necessitating regular maintenance of industrial boilers. Recent projections indicate that the industrial sector is expected to grow at a compound annual growth rate of 4% over the next five years. This growth translates into a higher demand for maintenance services to ensure that boilers operate efficiently and safely. Consequently, the Industrial Boiler Maintenance Market is likely to benefit from this upward trend in industrial activity.