Expansion of Industrial Sector

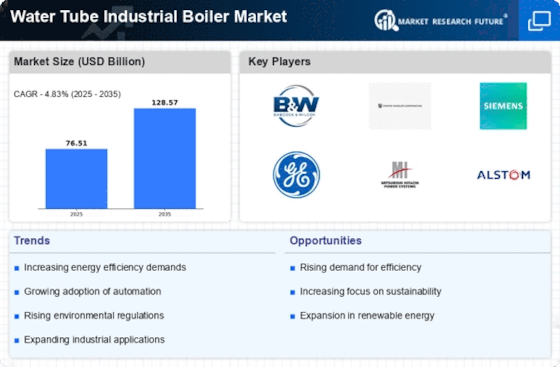

The Water Tube Industrial Boiler Market is poised for growth, largely due to the expansion of the industrial sector across various regions. Industries such as manufacturing, food processing, and pharmaceuticals are increasingly relying on water tube boilers for their steam generation needs. According to recent data, the manufacturing sector is projected to grow at a compound annual growth rate of approximately 4% over the next few years. This growth is likely to drive the demand for efficient and reliable steam generation solutions, positioning water tube boilers as a preferred choice for many industrial applications.

Increasing Demand for Energy Efficiency

The Water Tube Industrial Boiler Market is experiencing a notable shift towards energy efficiency, driven by rising energy costs and stringent regulations. Industries are increasingly adopting water tube boilers due to their superior efficiency compared to fire tube boilers. These systems can achieve efficiency levels exceeding 90%, which is crucial for industries aiming to reduce operational costs. Furthermore, the implementation of energy management systems is becoming prevalent, allowing for real-time monitoring and optimization of boiler performance. This trend is expected to propel the market as companies seek to minimize energy consumption and carbon emissions, aligning with global sustainability goals.

Rising Focus on Renewable Energy Sources

The Water Tube Industrial Boiler Market is increasingly influenced by the rising focus on renewable energy sources. As industries seek to transition towards more sustainable practices, the integration of biomass and other renewable fuels in water tube boilers is gaining traction. This shift not only helps in reducing carbon footprints but also aligns with global energy transition goals. The market is expected to expand as more companies invest in dual-fuel capabilities, allowing for flexibility in fuel choice and enhancing energy security. This trend indicates a promising future for water tube boilers in the context of renewable energy adoption.

Technological Innovations in Boiler Design

The Water Tube Industrial Boiler Market is witnessing a wave of technological innovations that enhance boiler performance and reliability. Recent advancements include the development of smart boilers equipped with IoT capabilities, allowing for remote monitoring and predictive maintenance. These innovations not only improve operational efficiency but also reduce downtime, which is critical for industries that rely on continuous steam supply. As technology continues to evolve, the market is likely to see an increase in the adoption of these advanced systems, further solidifying the position of water tube boilers in various industrial applications.

Regulatory Compliance and Environmental Standards

The Water Tube Industrial Boiler Market is significantly influenced by the need for compliance with environmental regulations. Governments worldwide are implementing stricter emissions standards, compelling industries to adopt cleaner technologies. Water tube boilers, known for their lower emissions and higher efficiency, are increasingly favored as they help companies meet these regulatory requirements. The market is expected to benefit from this trend, as industries seek to avoid penalties and enhance their sustainability profiles. Furthermore, the integration of advanced emission control technologies in water tube boilers is likely to further bolster their appeal in the market.