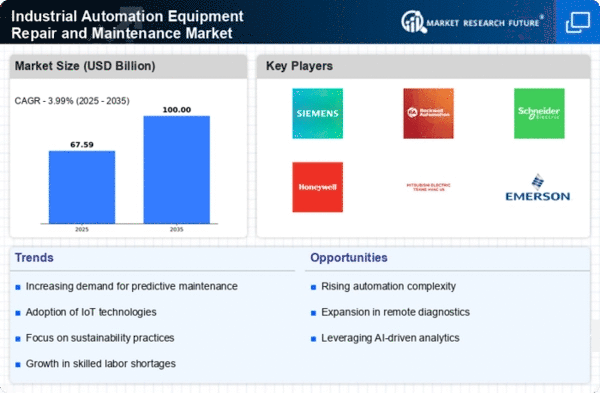

The Industrial Automation Equipment Repair and Maintenance Market is characterized by a dynamic competitive landscape, driven by technological advancements and increasing demand for operational efficiency across various sectors. Key players such as Siemens (DE), Rockwell Automation (US), and Schneider Electric (FR) are strategically positioned to leverage innovation and digital transformation. Siemens (DE) focuses on integrating AI and IoT into its service offerings, enhancing predictive maintenance capabilities. Meanwhile, Rockwell Automation (US) emphasizes partnerships with software firms to bolster its digital solutions, thereby improving customer engagement and operational insights. Schneider Electric (FR) is actively pursuing sustainability initiatives, aligning its repair and maintenance services with eco-friendly practices, which collectively shapes a competitive environment increasingly oriented towards technology and sustainability.

The market structure appears moderately fragmented, with a mix of established players and emerging firms. Key business tactics include localizing manufacturing to reduce lead times and optimizing supply chains to enhance service delivery. This collective influence of major players fosters a competitive atmosphere where agility and responsiveness are paramount, allowing companies to adapt to evolving customer needs and market demands.

In November 2025, Siemens (DE) announced the launch of its new digital maintenance platform, which utilizes advanced analytics to predict equipment failures before they occur. This strategic move is significant as it not only enhances Siemens' service portfolio but also positions the company as a leader in predictive maintenance solutions, potentially increasing customer loyalty and market share.

In October 2025, Rockwell Automation (US) expanded its partnership with a leading cloud service provider to enhance its data analytics capabilities. This collaboration is crucial as it enables Rockwell to offer more robust data-driven insights to its clients, thereby improving operational efficiency and reducing downtime. Such strategic alliances are indicative of a broader trend towards integrated solutions in the market.

In September 2025, Schneider Electric (FR) launched a new initiative aimed at reducing carbon emissions in its repair and maintenance operations. This initiative underscores the company's commitment to sustainability and reflects a growing trend among industry leaders to incorporate environmental considerations into their business strategies. By prioritizing eco-friendly practices, Schneider Electric not only enhances its brand image but also meets the increasing demand for sustainable solutions from customers.

As of December 2025, current competitive trends are heavily influenced by digitalization, sustainability, and the integration of AI technologies. Strategic alliances are increasingly shaping the landscape, allowing companies to pool resources and expertise to deliver innovative solutions. Looking ahead, competitive differentiation is likely to evolve from traditional price-based competition to a focus on innovation, technology, and supply chain reliability, as companies strive to meet the complex demands of a rapidly changing market.

Leave a Comment