Increasing Industrialization

The rapid pace of industrialization across various sectors appears to be a primary driver for the Industrial Anti-Scaling Chemicals Market. As industries expand, the need for efficient water management systems becomes paramount. Scaling in equipment can lead to significant operational inefficiencies and increased maintenance costs. Consequently, industries are increasingly adopting anti-scaling chemicals to mitigate these issues. According to recent data, the industrial sector is projected to grow at a compound annual growth rate of approximately 5.2% over the next few years, further fueling the demand for these chemicals. This trend indicates a robust market potential for anti-scaling solutions, as industries seek to enhance productivity and reduce downtime caused by scaling problems.

Growth in the Oil and Gas Sector

The oil and gas industry is experiencing a resurgence, which appears to be a key driver for the Industrial Anti-Scaling Chemicals Market. As exploration and production activities ramp up, the need for effective anti-scaling solutions becomes critical to maintain operational efficiency. Scaling can lead to significant production losses and increased maintenance costs in this sector. The market for anti-scaling chemicals is projected to grow in tandem with the oil and gas sector, which is expected to expand at a compound annual growth rate of approximately 4.8%. This growth indicates a robust demand for anti-scaling solutions, as companies seek to optimize their operations and mitigate the risks associated with scaling.

Rising Demand from Water Treatment Facilities

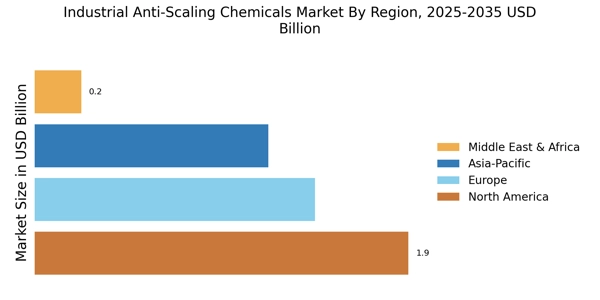

The increasing demand for water treatment solutions is a significant driver for the Industrial Anti-Scaling Chemicals Market. As water scarcity becomes a pressing issue, water treatment facilities are expanding their operations to ensure a reliable supply of clean water. Anti-scaling chemicals play a crucial role in maintaining the efficiency of water treatment processes by preventing scale buildup in pipes and equipment. The market for these chemicals is expected to grow as more facilities adopt advanced treatment technologies. Recent estimates indicate that the water treatment sector is likely to grow at a rate of 5.5%, thereby driving the demand for anti-scaling solutions. This trend underscores the importance of effective scaling management in ensuring the sustainability of water resources.

Regulatory Compliance and Environmental Standards

The stringent regulatory frameworks governing water quality and industrial emissions are likely to bolster the Industrial Anti-Scaling Chemicals Market. Governments and regulatory bodies are imposing stricter guidelines to ensure that industries minimize their environmental impact. This has led to an increased focus on the use of effective anti-scaling chemicals that not only enhance operational efficiency but also comply with environmental standards. Industries are compelled to adopt these chemicals to avoid penalties and ensure sustainable practices. The market for anti-scaling chemicals is expected to witness a growth rate of around 4.5% as companies strive to meet these regulatory requirements while maintaining their operational efficiency.

Technological Innovations in Chemical Formulations

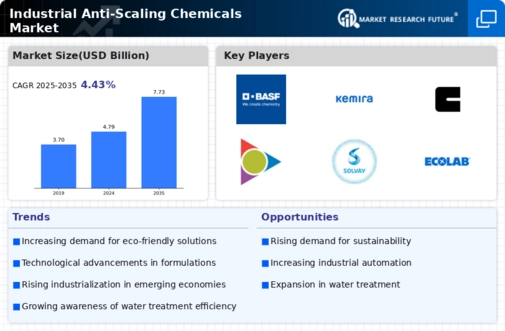

Technological advancements in the formulation of anti-scaling chemicals are significantly influencing the Industrial Anti-Scaling Chemicals Market. Innovations such as the development of more effective and environmentally friendly formulations are emerging. These advancements not only enhance the efficacy of anti-scaling agents but also reduce their environmental footprint. For instance, the introduction of bio-based anti-scaling chemicals is gaining traction, appealing to industries aiming for sustainable solutions. The market is projected to expand as these innovative products become more widely adopted, with an anticipated growth rate of 6% in the coming years. This trend suggests that companies investing in research and development of new formulations are likely to capture a larger market share.