North America : Innovation and Market Leadership

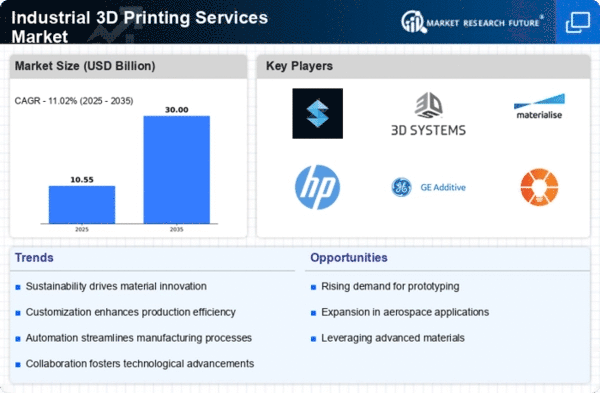

North America leads the Industrial 3D Printing Services market, holding a significant share of 4.75B in 2024. The region's growth is driven by advanced manufacturing technologies, increasing demand for customized solutions, and supportive government initiatives. Regulatory frameworks are evolving to promote innovation, ensuring a conducive environment for market expansion. The presence of major players like Stratasys and 3D Systems further fuels this growth, as they invest heavily in R&D and infrastructure.

The competitive landscape in North America is robust, with the U.S. being the primary market contributor. Companies are focusing on enhancing their service offerings and expanding their capabilities to meet diverse industry needs. The integration of AI and IoT in 3D printing processes is gaining traction, leading to improved efficiency and reduced costs. As a result, North America is poised to maintain its leadership position in the global market.

Europe : Emerging Market with Strong Potential

Europe's Industrial 3D Printing Services market is valued at 2.8B, reflecting a growing trend towards additive manufacturing across various sectors. The region benefits from strong regulatory support aimed at fostering innovation and sustainability. Initiatives from the European Union encourage the adoption of advanced manufacturing technologies, which are crucial for maintaining competitiveness in the global market. The increasing focus on reducing waste and enhancing production efficiency is driving demand for 3D printing solutions.

Leading countries in Europe include Germany, France, and the UK, where significant investments in 3D printing technologies are being made. Key players like Materialise and EOS are at the forefront, driving innovation and expanding their market presence. The competitive landscape is characterized by collaborations between technology providers and end-users, enhancing the overall ecosystem. As Europe continues to embrace 3D printing, it is expected to play a pivotal role in shaping the future of manufacturing.

Asia-Pacific : Rapid Growth and Adoption

The Asia-Pacific region is witnessing rapid growth in the Industrial 3D Printing Services market, currently valued at 1.8B. This growth is driven by increasing industrialization, a rising demand for customized products, and significant investments in technology. Countries like China and Japan are leading the charge, supported by government initiatives aimed at promoting advanced manufacturing. The region's regulatory environment is becoming more favorable, encouraging the adoption of 3D printing technologies across various sectors.

China stands out as a key player in the Asia-Pacific market, with numerous companies investing in 3D printing capabilities. The competitive landscape is evolving, with both established firms and startups vying for market share. Major players like HP and GE Additive are expanding their operations in the region, focusing on innovation and customer-centric solutions. As the Asia-Pacific market matures, it is expected to become a significant contributor to the global 3D printing landscape.

Middle East and Africa : Emerging Market with Challenges

The Middle East and Africa region represents a nascent market for Industrial 3D Printing Services, valued at 0.15B. Despite its small size, the region shows potential for growth driven by increasing awareness of 3D printing applications in various industries. Government initiatives aimed at diversifying economies and promoting technology adoption are beginning to take shape, although challenges remain in terms of infrastructure and investment. The regulatory landscape is evolving, with efforts to create a more conducive environment for innovation.

Countries like South Africa and the UAE are leading the way in adopting 3D printing technologies, with investments in research and development. The competitive landscape is still developing, with a mix of local and international players entering the market. As awareness and understanding of 3D printing benefits grow, the Middle East and Africa are expected to gradually increase their market share in the global arena.