North America : Innovation Hub for 3D Printing

North America dominates the Fused Deposition Modeling (FDM) 3D printing services market, holding a market size of $1.25B in 2025. The region's growth is driven by advancements in technology, increasing adoption across various industries, and supportive government initiatives. The demand for rapid prototyping and customized manufacturing solutions is on the rise, further propelling market expansion. Regulatory frameworks are also evolving to support innovation in additive manufacturing.

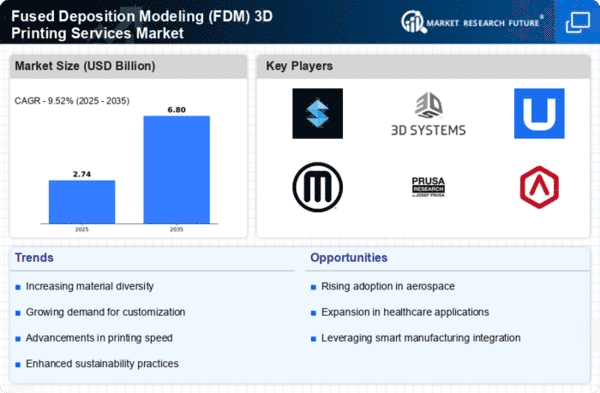

The competitive landscape in North America is robust, featuring key players such as Stratasys, 3D Systems, and MakerBot. The U.S. is the leading country, accounting for a significant share of the market, while Canada is also emerging as a notable player. The presence of established companies and a strong focus on R&D contribute to the region's leadership in FDM technology, ensuring continued growth and innovation.

Europe : Emerging Powerhouse in 3D Printing

Europe is witnessing significant growth in the Fused Deposition Modeling (FDM) 3D printing services market, with a market size of $0.75B in 2025. The region benefits from a strong manufacturing base, increasing investments in R&D, and a growing emphasis on sustainability. Regulatory support for additive manufacturing is also a key driver, as governments promote innovation and efficiency in production processes.

Leading countries in Europe include Germany, the Netherlands, and the Czech Republic, where companies like Ultimaker and Prusa Research are making strides. The competitive landscape is characterized by a mix of established firms and startups, fostering innovation. The European market is poised for growth as industries adopt FDM technology for various applications, from automotive to healthcare.

Asia-Pacific : Emerging Market for 3D Printing

The Asia-Pacific region is rapidly emerging in the Fused Deposition Modeling (FDM) 3D printing services market, with a market size of $0.4B in 2025. Key growth drivers include increasing industrialization, a surge in demand for customized products, and the expansion of the e-commerce sector. Governments are also implementing policies to support the adoption of advanced manufacturing technologies, which is expected to further boost market growth.

China and Japan are leading the way in FDM technology adoption, with companies like FlashForge and Anycubic gaining traction. The competitive landscape is evolving, with both local and international players vying for market share. As the region continues to invest in technology and infrastructure, the FDM market is set to expand significantly, catering to diverse industries such as education, healthcare, and consumer goods.

Middle East and Africa : Resource-Rich Frontier for 3D Printing

The Middle East and Africa region is in the nascent stages of developing its Fused Deposition Modeling (FDM) 3D printing services market, currently valued at $0.1B in 2025. The growth potential is significant, driven by increasing awareness of 3D printing applications and the need for localized manufacturing solutions. Governments are beginning to recognize the importance of additive manufacturing in diversifying their economies and enhancing industrial capabilities.

Countries like South Africa and the UAE are at the forefront of adopting FDM technology, with initiatives aimed at fostering innovation and entrepreneurship. The competitive landscape is still developing, with a mix of local startups and international firms entering the market. As investments in technology and infrastructure grow, the region is expected to see a gradual increase in FDM adoption across various sectors, including construction and healthcare.