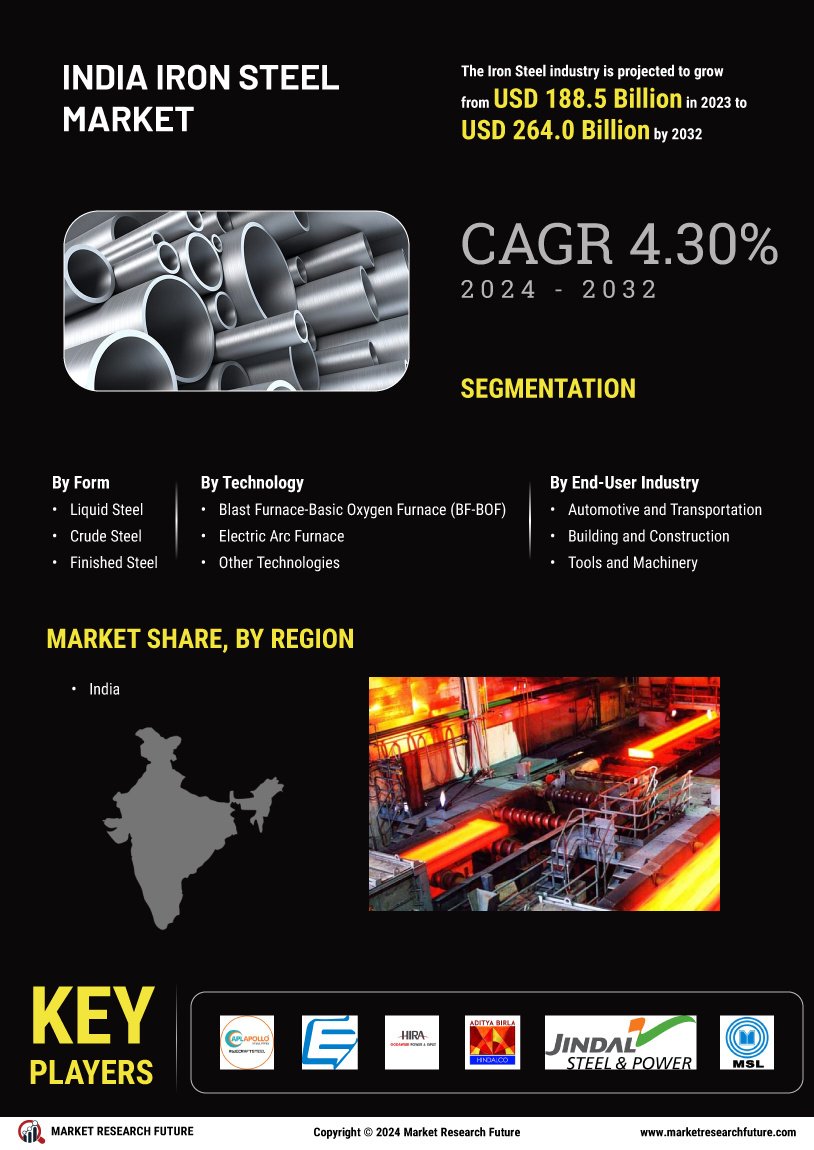

Growing Automotive Sector

The automotive sector in India is witnessing substantial growth, which is likely to have a significant impact on the India Iron Steel Market. With the rise in vehicle production and sales, the demand for high-quality steel is expected to increase correspondingly. The automotive industry is projected to reach a market size of USD 300 billion by 2026, necessitating a steady supply of steel for manufacturing vehicles. Additionally, the shift towards electric vehicles (EVs) is creating new opportunities for steel manufacturers to innovate and develop lighter, stronger materials. This transition is anticipated to drive demand for specialized steel products, further enhancing the market dynamics. As the automotive sector continues to expand, its influence on the India Iron Steel Market is expected to grow, fostering a symbiotic relationship between the two sectors.

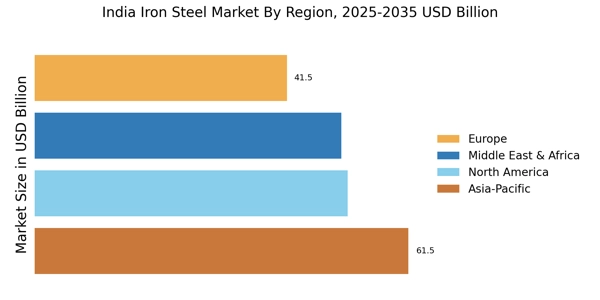

Increasing Export Opportunities

Increasing export opportunities are emerging as a vital driver for the India Iron Steel Market. With a growing global demand for steel, Indian manufacturers are strategically positioning themselves to tap into international markets. Recent data indicates that India's steel exports have surged, with a notable increase in shipments to countries in Southeast Asia and the Middle East. The government's initiatives to enhance trade relations and reduce export tariffs are likely to further facilitate this trend. Additionally, the emphasis on quality and compliance with international standards is enabling Indian steel producers to compete effectively on a global scale. As the world seeks reliable sources of steel, the potential for Indian exports to expand significantly could bolster the overall growth of the India Iron Steel Market.

Government Initiatives and Policies

Government initiatives and policies play a crucial role in shaping the India Iron Steel Market. The Make in India initiative, aimed at boosting domestic manufacturing, has led to increased investments in the steel sector. Additionally, the National Steel Policy 2017 outlines ambitious targets for production and consumption, aiming for a capacity of 300 million tonnes by 2030. Such policies not only encourage foreign direct investment but also promote technological advancements within the industry. The government's focus on enhancing the ease of doing business and reducing compliance burdens is likely to attract more players into the market. Furthermore, initiatives aimed at promoting sustainable practices in steel production could lead to a more environmentally friendly industry, aligning with global trends. Overall, these government measures are expected to create a conducive environment for growth in the India Iron Steel Market.

Rising Demand from Construction Sector

The construction sector in India is experiencing robust growth, which appears to be a primary driver for the India Iron Steel Market. With the government's focus on infrastructure development, including housing, roads, and bridges, the demand for steel is projected to rise significantly. According to recent estimates, the construction sector is expected to contribute approximately 8-10% to India's GDP by 2025. This surge in construction activities necessitates a substantial increase in steel production, thereby bolstering the India Iron Steel Market. Furthermore, the push for affordable housing under various government schemes is likely to further amplify the demand for steel, as it is a fundamental material in building structures. Consequently, the interplay between construction growth and steel demand is poised to shape the market landscape in the coming years.

Technological Innovations in Steel Production

Technological innovations are transforming the India Iron Steel Market, enhancing efficiency and productivity. The adoption of advanced manufacturing techniques, such as automation and artificial intelligence, is streamlining production processes. For instance, the implementation of smart manufacturing solutions is expected to reduce operational costs and improve product quality. Moreover, the development of new steel grades and alloys is catering to the evolving needs of various sectors, including automotive and construction. As per industry reports, the integration of Industry 4.0 technologies could potentially increase production efficiency by up to 30%. This technological shift not only positions Indian steel manufacturers competitively on the global stage but also aligns with the increasing demand for high-performance materials. Consequently, the ongoing technological advancements are likely to be a pivotal driver for the India Iron Steel Market.