Rising Labor Costs

Increasing labor costs in India are compelling manufacturers to seek automation solutions within the artificial industrial-in-manufacturing market. As wages rise, companies are exploring AI and robotics to maintain competitiveness and reduce operational expenses. The cost of labor in India has seen an annual increase of approximately 8%, prompting a shift towards automated systems that can perform tasks traditionally done by human workers. This trend is likely to accelerate the adoption of AI technologies, as businesses aim to optimize their workforce and enhance productivity, thereby driving market growth.

Technological Advancements in AI

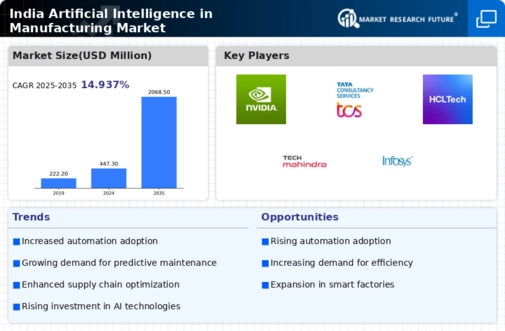

The rapid evolution of artificial intelligence (AI) technologies is a primary driver for the artificial industrial-in-manufacturing market. In India, advancements in machine learning, computer vision, and natural language processing are enhancing operational efficiencies. For instance, AI-driven predictive maintenance solutions can reduce downtime by up to 30%, thereby increasing productivity. The integration of AI in robotics is also transforming manufacturing processes, allowing for greater precision and speed. As companies increasingly adopt these technologies, the market is projected to grow at a CAGR of 25% over the next five years, indicating a robust demand for AI solutions in manufacturing.

Increased Focus on Quality Control

Quality control remains a critical aspect of manufacturing, and the artificial industrial-in-manufacturing market is responding to this need through advanced AI solutions. In India, manufacturers are leveraging AI-driven inspection systems to enhance product quality and reduce defects. These systems can analyze products at a speed and accuracy that surpasses human capabilities, leading to a decrease in rejection rates by up to 15%. As quality standards continue to rise, the demand for AI technologies in quality assurance is expected to grow, further propelling the artificial industrial-in-manufacturing market.

Government Initiatives and Policies

The Indian government has been actively promoting the adoption of artificial industrial-in-manufacturing market technologies through various initiatives. Programs such as 'Make in India' and 'Digital India' aim to enhance manufacturing capabilities and encourage the use of advanced technologies. Financial incentives, tax benefits, and subsidies for companies investing in AI and automation are also being offered. This supportive policy environment is expected to drive market growth, with an estimated increase in investment in AI technologies reaching $10 billion by 2026. Such initiatives are likely to create a conducive ecosystem for the artificial industrial-in-manufacturing market.

Demand for Customization and Flexibility

The growing consumer demand for customized products is influencing the artificial industrial-in-manufacturing market in India. Manufacturers are increasingly required to adapt their production processes to meet specific customer needs, which necessitates the integration of AI technologies. These technologies enable real-time data analysis and agile manufacturing practices, allowing companies to respond swiftly to market changes. As a result, the market is expected to expand, with projections indicating a potential growth rate of 20% over the next few years. This demand for flexibility is reshaping manufacturing strategies and driving investments in AI solutions.