Government Initiatives and Policies

The Indian government has been actively promoting the adoption of artificial intelligence in manufacturing through various initiatives and policies. The 'Make in India' campaign, launched in 2014, aims to enhance the manufacturing sector's contribution to the GDP, which is projected to reach 25 percent by 2025. Additionally, the National AI Strategy emphasizes the importance of AI in driving economic growth and innovation. The government has also introduced funding schemes and incentives for startups and established companies to invest in AI technologies. This supportive regulatory environment is likely to accelerate the growth of the India Artificial Intelligence in Manufacturing Market, as businesses seek to leverage AI for improved efficiency and competitiveness.

Integration of IoT and AI Technologies

The integration of Internet of Things (IoT) and artificial intelligence technologies is transforming the manufacturing landscape in India. IoT devices collect vast amounts of data from manufacturing processes, which can be analyzed using AI algorithms to derive actionable insights. This synergy enables predictive maintenance, real-time monitoring, and enhanced decision-making capabilities. the India Artificial Intelligence in Manufacturing Market is likely to see substantial growth as companies increasingly adopt IoT-enabled AI solutions. Reports suggest that the IoT market in India is expected to reach USD 15 billion by 2025, further fueling the demand for AI applications in manufacturing. This integration not only improves operational efficiency but also fosters innovation in product development.

Rising Demand for Smart Manufacturing Solutions

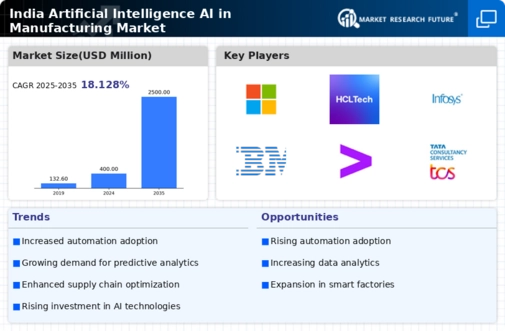

The demand for smart manufacturing solutions in India is on the rise, driven by the need for increased efficiency and productivity. Industries are increasingly adopting AI technologies to optimize production processes, reduce downtime, and enhance product quality. According to recent estimates, the smart manufacturing market in India is expected to grow at a CAGR of over 30 percent from 2021 to 2026. This growth is indicative of the broader trend towards digital transformation in manufacturing, where AI plays a crucial role. the India Artificial Intelligence in Manufacturing Market is thus poised to benefit from this shift, as companies invest in AI-driven tools and systems to remain competitive in a rapidly evolving landscape.

Increased Investment in Research and Development

Investment in research and development (R&D) is a key driver of innovation in the India Artificial Intelligence in Manufacturing Market. Companies are allocating significant resources to develop AI-driven solutions that enhance manufacturing processes. The Indian government has also recognized the importance of R&D in fostering technological advancements and has introduced various funding schemes to support AI research. According to industry reports, R&D spending in the manufacturing sector is expected to increase by 20 percent annually over the next five years. This influx of investment is likely to lead to the development of cutting-edge AI applications, further propelling the growth of the India artificial intelligence in manufacturing market.

Focus on Skill Development and Workforce Training

As the India Artificial Intelligence in Manufacturing Market expands, there is a growing emphasis on skill development and workforce training. The successful implementation of AI technologies requires a skilled workforce capable of managing and interpreting AI systems. The government, along with private sector players, is investing in training programs to equip workers with the necessary skills. Initiatives such as the Skill India Mission aim to train millions of individuals in advanced manufacturing technologies, including AI. This focus on skill development is crucial for ensuring that the workforce is prepared to meet the demands of an increasingly automated manufacturing environment, thereby supporting the growth of the India artificial intelligence in manufacturing market.