Customization Trends

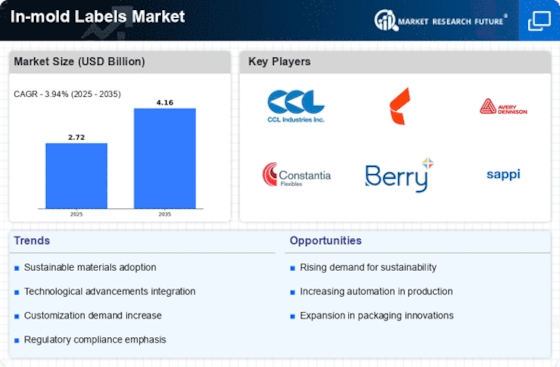

Customization is emerging as a key driver in the In-mold Labels Market, as brands seek to create unique identities for their products. The ability to produce labels tailored to specific customer needs allows companies to enhance brand recognition and consumer engagement. This trend is particularly evident in sectors such as cosmetics and personal care, where personalized packaging can significantly influence purchasing decisions. The market is responding to this demand by offering more flexible production options, enabling shorter runs and quicker turnaround times. As a result, the customization trend is expected to propel market growth, with estimates suggesting an increase in market value by approximately 8% over the next few years.

Regulatory Compliance

Regulatory compliance is becoming increasingly important within the In-mold Labels Market, as governments worldwide implement stricter labeling requirements. These regulations often focus on safety, environmental impact, and consumer information, compelling manufacturers to adapt their labeling practices accordingly. Companies that proactively address these compliance issues are likely to gain a competitive advantage, as they can ensure their products meet legal standards while also appealing to consumer preferences for transparency. The market is expected to see a shift towards labels that not only comply with regulations but also enhance product safety and sustainability. This focus on compliance could drive market growth by an estimated 5% in the coming years.

Rising Demand in Packaging

The In-mold Labels Market is experiencing a surge in demand driven by the packaging sector. As consumer preferences shift towards convenience and aesthetic appeal, brands are increasingly utilizing in-mold labels for their packaging solutions. These labels offer durability and resistance to wear and tear, making them ideal for various applications, including food and beverage packaging. Market data suggests that the packaging segment accounts for a substantial share of the in-mold labels market, with expectations of continued growth as more companies recognize the benefits of using in-mold labels. This trend is likely to contribute to an overall market expansion of around 6% in the next few years.

Sustainability Initiatives

The increasing emphasis on sustainability within the In-mold Labels Market is driving demand for eco-friendly labeling solutions. Manufacturers are increasingly adopting biodegradable and recyclable materials to meet consumer preferences for sustainable products. This shift is not merely a trend but a response to regulatory pressures and consumer awareness regarding environmental issues. As a result, the market for sustainable in-mold labels is projected to grow significantly, with estimates suggesting a compound annual growth rate of over 5% in the coming years. Companies that prioritize sustainability in their product offerings are likely to gain a competitive edge, appealing to environmentally conscious consumers and businesses alike.

Technological Advancements

Technological innovations are playing a pivotal role in shaping the In-mold Labels Market. The integration of advanced printing technologies, such as digital printing and flexographic printing, enhances the quality and efficiency of label production. These advancements allow for high-resolution graphics and intricate designs, which are increasingly demanded by brands seeking to differentiate their products. Furthermore, the adoption of automation in production processes is expected to reduce costs and improve turnaround times. As a result, the market is witnessing a shift towards more sophisticated labeling solutions, with projections indicating a potential increase in market size by approximately 7% over the next five years.