Expansion of Renewable Energy Sector

The Impression Die Forging Market is likely to benefit from the expansion of the renewable energy sector, particularly in wind and solar energy applications. As the world shifts towards sustainable energy sources, the demand for robust and reliable components is increasing. Wind turbine manufacturing, for instance, requires high-strength forged parts to ensure durability and efficiency. Recent projections suggest that investments in renewable energy infrastructure could grow by 8% annually, creating a substantial opportunity for the Impression Die Forging Market to supply essential components that support this transition.

Increased Investment in Infrastructure

The Impression Die Forging Market is poised to gain from heightened investments in infrastructure development across various regions. Governments are allocating substantial budgets for the construction and renovation of roads, bridges, and buildings, which necessitates the use of high-strength forged components. For instance, recent reports indicate that infrastructure spending is expected to rise by 6% annually, creating a robust demand for forged products. This trend not only supports the growth of the Impression Die Forging Market but also encourages innovation in forging techniques to meet the evolving needs of construction projects.

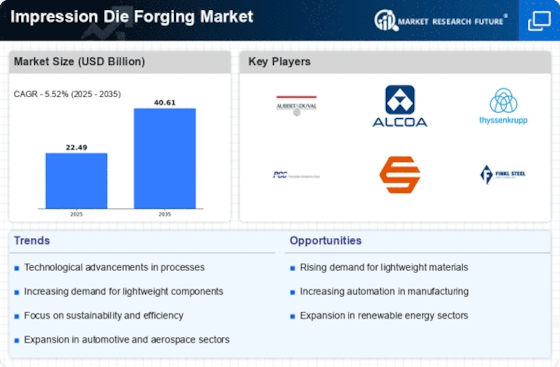

Rising Demand for Lightweight Components

The Impression Die Forging Market is experiencing a notable increase in demand for lightweight components, particularly in sectors such as automotive and aerospace. Manufacturers are increasingly seeking materials that reduce overall weight while maintaining structural integrity. This trend is driven by the need for improved fuel efficiency and performance. According to recent data, the automotive sector alone is projected to witness a growth rate of approximately 4.5% annually, with lightweight materials playing a crucial role. As industries strive to meet stringent regulatory standards for emissions, the Impression Die Forging Market is likely to benefit from this shift towards lighter, more efficient components.

Growing Demand for High-Performance Alloys

The Impression Die Forging Market is witnessing a surge in demand for high-performance alloys, particularly in sectors that require exceptional strength and durability. Industries such as aerospace and defense are increasingly utilizing advanced materials that can withstand extreme conditions. Recent market analysis indicates that the demand for titanium and nickel-based alloys is expected to grow by 5% annually, driven by their superior properties. This trend not only enhances the performance of forged components but also positions the Impression Die Forging Market as a key player in supplying materials that meet rigorous industry standards.

Technological Innovations in Forging Processes

Technological advancements are significantly influencing the Impression Die Forging Market. Innovations such as computer numerical control (CNC) machining and automation are enhancing precision and efficiency in forging processes. These technologies allow manufacturers to produce complex geometries with reduced waste, thereby improving overall productivity. Recent statistics suggest that the adoption of advanced manufacturing technologies could lead to a 20% reduction in production costs. As companies strive to remain competitive, the integration of these technologies into the Impression Die Forging Market is likely to accelerate, fostering growth and development.