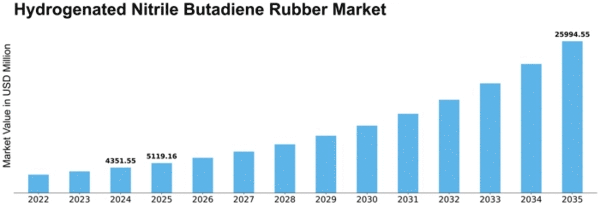

Hydrogenated Nitrile Butadiene Rubber Size

Hydrogenated Nitrile Butadiene Rubber Market Growth Projections and Opportunities

HNBR, derived from nitrile rubber through a hydrogenation process using precious metal catalysts, represents an advanced class of chemically modified NBR. Its superior wear and extrusion resistance, along with favorable chemical compatibility with various fluids and gases, set it apart from traditional NBR. HNBR exhibits outstanding resistance to mineral oil-based hydraulic fluids, animal and vegetable fats, diesel fuel, and diluted acids and bases. Especially recommended for applications demanding high heat, ozone resilience, and abrasion resistance, such as automotive components, HNBR has gained prominence. The automotive sector emerges as the primary consumer of HNBR, utilizing it in dynamic and static hoses, seals, gaskets, and belts. Additionally, HNBR finds extensive use in industrial sealing applications, particularly in oilfield scenarios.

The hydrogenation process, a crucial step in producing HNBR, imparts unique features that differentiate it from standard NBR. This includes heightened resistance to wear and extrusion, making it an ideal choice for applications where durability is paramount. HNBR's exceptional chemical compatibility extends to various fluids and gases, enhancing its versatility. Notably, it exhibits remarkable resilience against mineral oil-based hydraulic fluids, animal and vegetable fats, diesel fuel, as well as diluted acids and bases. This broad chemical resistance contributes to its effectiveness in diverse environments.

In the automotive industry, HNBR has carved a niche as a material of choice for dynamic and static hoses, seals, gaskets, and belts. The sector benefits significantly from HNBR's ability to withstand high temperatures, ozone exposure, and abrasion, ensuring reliable performance in demanding conditions. Moreover, its utilization extends beyond automotive applications, finding substantial use in industrial settings, particularly in oilfield operations where sealing reliability is critical. The distinct advantages offered by HNBR over traditional NBR underscore its increasing adoption and widespread use across various industries. The hydrogenation process not only enhances HNBR's resistance to wear and extrusion but also contributes to its durability, making it an optimal choice for challenging environments. Its remarkable chemical resistance to diverse substances, including hydraulic fluids, fuels, and acids, adds to its versatility. In the automotive industry, HNBR's resilience in hoses, seals, gaskets, and belts ensures long-lasting performance. Its widespread adoption in industrial applications, particularly in oilfield operations, highlights its reliability in critical sealing functions. HNBR's unique properties continue to position it as a favored material across sectors where durability and chemical resilience are paramount.

Leave a Comment