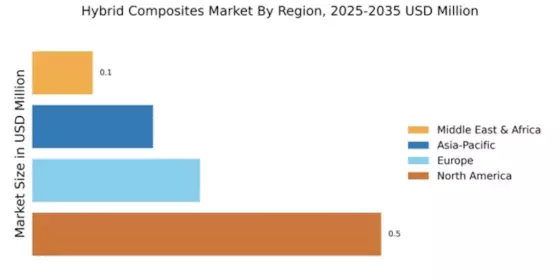

North America : Market Leader in Hybrid Composites

North America is poised to maintain its leadership in the hybrid composites market, holding a significant market share of 52% in 2024. The region's growth is driven by increasing demand in aerospace, automotive, and construction sectors, alongside supportive regulations promoting lightweight materials. The push for sustainability and energy efficiency further fuels this demand, making hybrid composites a preferred choice for manufacturers.

The United States stands out as the leading country, hosting major players like Hexcel Corporation and DuPont de Nemours, Inc. The competitive landscape is characterized by innovation and strategic partnerships among key companies such as Toray Industries and BASF SE. This dynamic environment fosters advancements in hybrid composite technologies, ensuring North America's continued dominance in the global market.

Europe : Emerging Market with Growth Potential

Europe is witnessing a notable rise in the hybrid composites market, with a market share of 25% in 2024. The region's growth is propelled by stringent regulations aimed at reducing carbon emissions and enhancing energy efficiency. Countries are increasingly adopting hybrid composites in automotive and aerospace applications, driven by the need for lightweight materials that improve fuel efficiency and performance.

Germany and France are leading the charge, with significant investments in research and development. Key players like Solvay SA and BASF SE are actively involved in this market, focusing on innovative solutions. The competitive landscape is robust, with a mix of established companies and emerging startups, fostering a vibrant ecosystem for hybrid composites in Europe.

Asia-Pacific : Rapid Growth in Hybrid Composites

Asia-Pacific is rapidly emerging as a significant player in the hybrid composites market, holding an 18% market share in 2024. The region's growth is driven by increasing industrialization, urbanization, and a rising demand for lightweight materials in automotive and aerospace sectors. Government initiatives promoting advanced manufacturing technologies further catalyze this growth, making hybrid composites a focal point for innovation.

China and Japan are at the forefront, with major companies like Mitsubishi Chemical Corporation and Teijin Limited leading the market. The competitive landscape is evolving, with both domestic and international players vying for market share. This dynamic environment is fostering advancements in hybrid composite technologies, positioning Asia-Pacific as a key region in the global market.

Middle East and Africa : Emerging Market with Challenges

The Middle East and Africa region is gradually developing its hybrid composites market, currently holding a 9% market share in 2024. The growth is primarily driven by increasing investments in infrastructure and construction projects, alongside a growing awareness of the benefits of lightweight materials. However, challenges such as limited manufacturing capabilities and regulatory hurdles may hinder rapid growth in this sector.

Countries like South Africa and the UAE are leading the way, with initiatives aimed at enhancing local manufacturing capabilities. The presence of key players is still limited, but companies are beginning to explore opportunities in this emerging market. As the region continues to develop, hybrid composites are expected to play a crucial role in various applications, particularly in construction and automotive sectors.