Focus on Operational Efficiency

The focus on operational efficiency is a driving force in the Horizontal Machining Center Market. Companies are increasingly seeking ways to optimize their production processes, reduce waste, and lower costs. Horizontal machining centers, known for their high-speed capabilities and reduced cycle times, are becoming essential tools for achieving these objectives. Recent studies indicate that manufacturers utilizing horizontal machining centers can improve their operational efficiency by up to 30%. This emphasis on efficiency is likely to lead to a rise in the adoption of horizontal machining centers, as businesses aim to enhance their competitiveness in a rapidly evolving market.

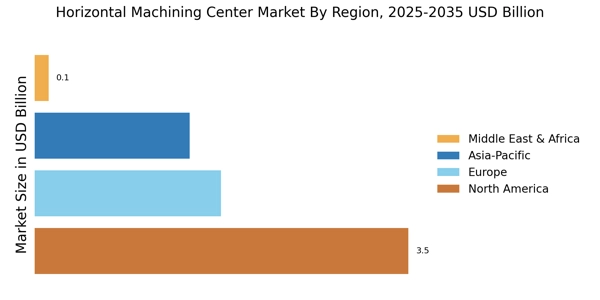

Growth of the Manufacturing Sector

The Horizontal Machining Center Market is significantly influenced by the overall growth of the manufacturing sector. As economies recover and expand, the demand for efficient and high-quality manufacturing processes rises. The manufacturing sector is projected to grow at a steady rate of around 5% annually, driven by increased production activities and the need for advanced machining solutions. This growth is likely to result in higher investments in horizontal machining centers, as manufacturers seek to enhance their operational efficiency and product quality. Furthermore, the trend towards reshoring and local production is expected to bolster the demand for horizontal machining centers, thereby positively impacting the Horizontal Machining Center Market.

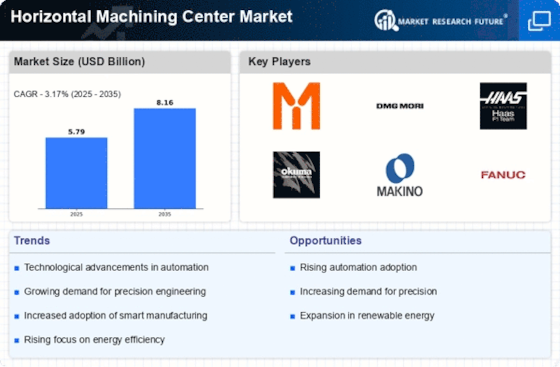

Rising Demand for Precision Engineering

The Horizontal Machining Center Market is experiencing a notable surge in demand for precision engineering across various sectors, including aerospace, automotive, and medical devices. As industries increasingly prioritize accuracy and efficiency, the need for advanced machining solutions becomes paramount. According to recent data, the precision engineering sector is projected to grow at a compound annual growth rate of approximately 7% over the next five years. This growth is likely to drive investments in horizontal machining centers, which are renowned for their ability to deliver high precision and complex geometries. Consequently, manufacturers are compelled to adopt these advanced technologies to remain competitive, thereby propelling the Horizontal Machining Center Market forward.

Technological Advancements in Machining

Technological advancements play a crucial role in shaping the Horizontal Machining Center Market. Innovations such as computer numerical control (CNC) and integrated automation systems enhance the capabilities of horizontal machining centers, allowing for increased productivity and reduced operational costs. The integration of artificial intelligence and machine learning into machining processes is also gaining traction, enabling predictive maintenance and real-time monitoring. As a result, manufacturers are likely to invest in state-of-the-art horizontal machining centers to leverage these technologies. Market data indicates that the adoption of advanced machining technologies is expected to increase by 15% in the coming years, further stimulating growth in the Horizontal Machining Center Market.

Customization and Flexibility in Production

Customization and flexibility are becoming increasingly vital in the Horizontal Machining Center Market. As customer preferences shift towards personalized products, manufacturers are compelled to adopt flexible machining solutions that can accommodate varying production requirements. Horizontal machining centers are particularly well-suited for this purpose, as they can be easily reconfigured for different tasks. Market analysis suggests that the demand for customizable machining solutions is likely to grow by 10% over the next few years, as companies strive to meet the diverse needs of their clients. This trend is expected to drive further investments in horizontal machining centers, enhancing their role in the manufacturing landscape.