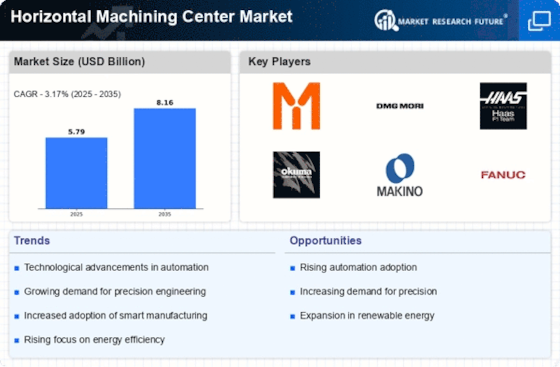

The Horizontal Machining Center Market is currently characterized by a dynamic competitive landscape, driven by technological advancements and increasing demand for precision engineering across various industries. Key players such as Mazak (Japan), DMG Mori (Germany), and Haas Automation (US) are at the forefront, each adopting distinct strategies to enhance their market positioning. Mazak (Japan) emphasizes innovation through continuous investment in R&D, focusing on advanced automation and smart manufacturing solutions. DMG Mori (Germany) has been actively pursuing strategic partnerships to bolster its technological capabilities, while Haas Automation (US) is concentrating on expanding its production capacity to meet the growing global demand. Collectively, these strategies contribute to a competitive environment that is increasingly focused on technological differentiation and operational efficiency.

In terms of business tactics, companies are increasingly localizing manufacturing to reduce lead times and optimize supply chains. The market structure appears moderately fragmented, with several key players exerting influence while also facing competition from emerging manufacturers. This fragmentation allows for a diverse range of offerings, catering to various customer needs and preferences, thereby enhancing overall market competitiveness.

In August 2025, DMG Mori (Germany) announced the launch of a new series of eco-friendly horizontal machining centers designed to minimize energy consumption and reduce waste. This strategic move not only aligns with global sustainability trends but also positions DMG Mori as a leader in environmentally conscious manufacturing solutions. The introduction of these machines is likely to attract customers who prioritize sustainability in their operations, thereby enhancing DMG Mori's market share.

In September 2025, Mazak (Japan) unveiled its latest digital manufacturing platform, which integrates AI and IoT technologies to optimize machining processes. This initiative reflects Mazak's commitment to digital transformation and positions the company to leverage data analytics for improved operational efficiency. By adopting such advanced technologies, Mazak is likely to enhance its competitive edge, appealing to manufacturers seeking to modernize their production capabilities.

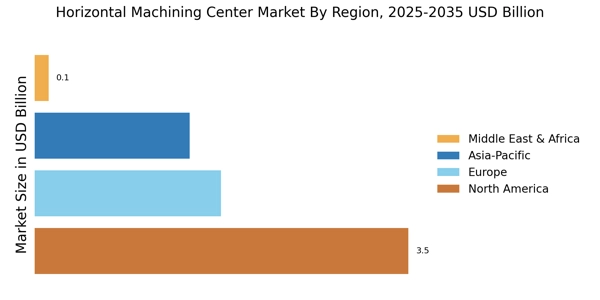

In October 2025, Haas Automation (US) expanded its global footprint by establishing a new manufacturing facility in Mexico. This strategic expansion aims to enhance production capabilities and reduce shipping times for North American customers. By localizing production, Haas Automation is expected to improve its supply chain reliability and responsiveness, which are critical factors in maintaining competitiveness in the market.

As of October 2025, the Horizontal Machining Center Market is witnessing significant trends such as digitalization, sustainability, and the integration of AI technologies. Strategic alliances among key players are shaping the competitive landscape, fostering innovation and collaboration. Looking ahead, it appears that competitive differentiation will increasingly hinge on technological advancements and supply chain reliability, rather than solely on price. Companies that prioritize innovation and sustainable practices are likely to emerge as leaders in this evolving market.