Expansion in Medical Applications

The High-Performance Polyethylene Market is witnessing a growing interest from the medical sector, particularly in the production of medical devices and implants. HPPE's biocompatibility and resistance to wear and tear make it suitable for various applications, including surgical instruments and orthopedic implants. The increasing prevalence of chronic diseases and the aging population are driving the demand for advanced medical solutions. In 2025, the medical applications segment is expected to contribute significantly to the overall HPPE market, as healthcare providers seek durable and reliable materials. This trend suggests a promising future for HPPE in the medical field, potentially leading to innovations that enhance patient care and outcomes.

Growing Demand in Packaging Solutions

The High-Performance Polyethylene Market is experiencing a significant uptick in demand for packaging solutions, driven by the need for lightweight, durable, and recyclable materials. HPPE's excellent barrier properties and resistance to chemicals make it an ideal choice for packaging applications across various sectors, including food and beverage, consumer goods, and pharmaceuticals. As sustainability becomes a priority for consumers and manufacturers alike, the shift towards eco-friendly packaging solutions is likely to bolster the HPPE market. In 2025, the packaging segment is expected to represent a substantial portion of the overall demand for HPPE, reflecting a broader trend towards sustainable practices in the industry.

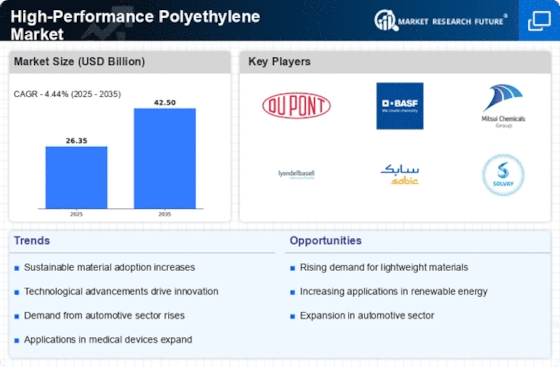

Rising Demand in Automotive Applications

The High-Performance Polyethylene Market is experiencing a notable surge in demand from the automotive sector. This is primarily due to the increasing need for lightweight materials that enhance fuel efficiency and reduce emissions. High-performance polyethylene (HPPE) offers superior strength-to-weight ratios, making it an attractive option for manufacturers aiming to meet stringent environmental regulations. In 2025, the automotive industry is projected to account for a significant share of the HPPE market, driven by innovations in vehicle design and the push towards electric vehicles. As automakers seek to improve performance while adhering to sustainability goals, the adoption of HPPE is likely to expand, indicating a robust growth trajectory for the market.

Technological Innovations in Manufacturing

Technological advancements in the production processes of high-performance polyethylene are playing a crucial role in shaping the market landscape. Innovations such as advanced polymerization techniques and improved processing methods are enhancing the quality and performance of HPPE products. These developments not only increase production efficiency but also reduce costs, making HPPE more accessible to various industries. In 2025, the High-Performance Polyethylene Market is likely to benefit from these technological improvements, as manufacturers strive to meet the evolving demands of end-users. The integration of automation and smart manufacturing practices may further streamline operations, indicating a transformative phase for the HPPE market.

Increased Investment in Research and Development

Investment in research and development within the High-Performance Polyethylene Market is anticipated to drive innovation and product diversification. Companies are increasingly focusing on developing new grades of HPPE that cater to specific applications, enhancing performance characteristics such as thermal stability and chemical resistance. This trend is likely to foster collaboration between manufacturers and research institutions, leading to breakthroughs that could redefine the capabilities of HPPE. In 2025, the emphasis on R&D is expected to yield new products that meet the stringent requirements of various industries, thereby expanding the market and creating new opportunities for growth.