North America : Market Leader in Repair Services

North America is poised to maintain its leadership in the Heavy Equipment Electrical Systems Repair Services Market, holding a market size of $4.25 billion. Key growth drivers include the increasing demand for advanced machinery in construction and mining sectors, alongside stringent regulations promoting equipment safety and efficiency. The region's robust infrastructure investments further catalyze market expansion, ensuring a steady demand for repair services.

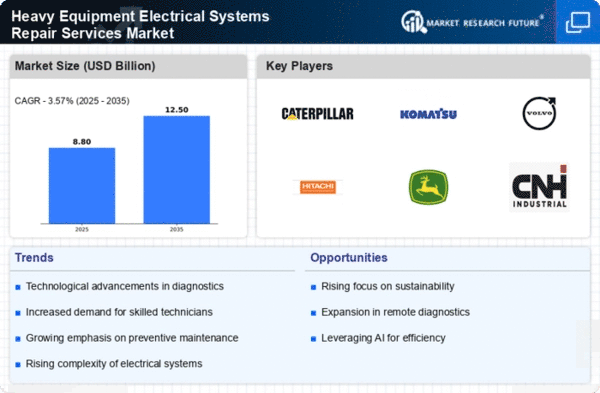

The competitive landscape is characterized by major players such as Caterpillar Inc, John Deere, and Terex Corporation, which dominate the market with innovative solutions and extensive service networks. The U.S. and Canada are the leading countries, benefiting from a well-established supply chain and technological advancements. This competitive edge is crucial for maintaining market share and meeting the evolving needs of customers.

Europe : Emerging Market with Growth Potential

Europe's Heavy Equipment Electrical Systems Repair Services Market is valued at $2.5 billion, driven by increasing investments in infrastructure and a shift towards sustainable practices. Regulatory frameworks aimed at reducing emissions and enhancing safety standards are pivotal in shaping market dynamics. The demand for efficient repair services is further fueled by the growing adoption of electric and hybrid machinery across various sectors.

Leading countries such as Germany, France, and the UK are at the forefront of this market, with a competitive landscape featuring key players like Volvo Group and JCB. The presence of established manufacturers and a focus on innovation create a conducive environment for market growth. As the region adapts to new technologies, the repair services sector is expected to expand significantly, catering to the evolving needs of the industry.

Asia-Pacific : Rapidly Growing Market Landscape

The Asia-Pacific region, with a market size of $1.75 billion, is witnessing rapid growth in the Heavy Equipment Electrical Systems Repair Services Market. This growth is driven by increasing urbanization, infrastructure development, and a rising demand for heavy machinery in construction and mining. Government initiatives aimed at enhancing industrial capabilities and safety regulations are also contributing to market expansion, making it a key area for investment.

Countries like China, Japan, and India are leading the charge, with a competitive landscape that includes major players such as Komatsu Ltd and Hitachi Construction Machinery. The region's diverse market dynamics and the presence of both established and emerging companies create a vibrant environment for repair services. As the demand for advanced machinery continues to rise, the repair services sector is expected to flourish, catering to the needs of various industries.

Middle East and Africa : Emerging Market with Untapped Potential

The Middle East and Africa region, valued at $0.9 billion, presents significant growth opportunities in the Heavy Equipment Electrical Systems Repair Services Market. The region's economic diversification efforts and investments in infrastructure projects are key drivers of market demand. Additionally, regulatory initiatives aimed at improving safety standards and operational efficiency are fostering a conducive environment for repair services to thrive.

Leading countries such as South Africa and the UAE are emerging as key players in this market, with a competitive landscape that includes both local and international companies. The presence of major players like Doosan Infracore and CNH Industrial N.V. enhances the market's competitiveness. As the region continues to develop its infrastructure, the demand for reliable repair services is expected to increase, paving the way for future growth.