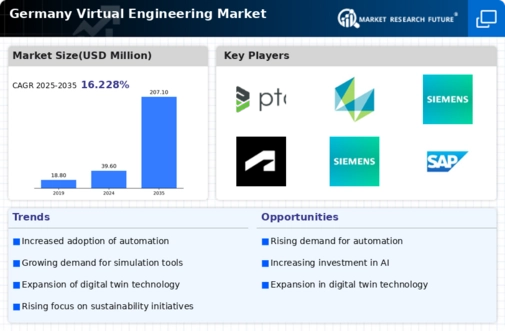

Growing Focus on Industry 4.0

The transition towards Industry 4.0 is a significant driver in the Germany virtual engineering market. This paradigm shift emphasizes the integration of smart technologies, automation, and data exchange in manufacturing processes. In 2025, approximately 70% of German manufacturers reported implementing Industry 4.0 strategies, highlighting the urgency to adopt virtual engineering solutions. The use of virtual engineering tools facilitates the design and simulation of smart factories, enabling companies to enhance productivity and reduce time-to-market. Furthermore, the emphasis on interconnected systems and real-time data analytics aligns with the capabilities offered by virtual engineering technologies. As the demand for smart manufacturing continues to rise, the Germany virtual engineering market is poised for substantial growth.

Rising Demand for Digital Twins

The increasing adoption of digital twin technology is a key driver in the Germany virtual engineering market. Digital twins enable real-time simulation and monitoring of physical assets, which enhances operational efficiency and reduces costs. In 2025, the market for digital twins in Germany was valued at approximately 1.5 billion euros, reflecting a compound annual growth rate of around 25%. This trend is likely to continue as industries such as manufacturing and automotive increasingly rely on virtual engineering solutions to optimize processes and improve product lifecycle management. The integration of digital twins with IoT devices further amplifies their potential, allowing for predictive maintenance and better decision-making. As companies seek to innovate and remain competitive, the demand for digital twin technology is expected to drive growth in the Germany virtual engineering market.

Government Initiatives and Funding

Government initiatives aimed at promoting digitalization and innovation play a crucial role in the Germany virtual engineering market. The German government has launched several funding programs to support research and development in virtual engineering technologies. For instance, the 'Digital Strategy 2025' initiative aims to enhance the digital infrastructure across various sectors, including manufacturing and engineering. In 2025, the government allocated over 1 billion euros to support projects that leverage virtual engineering solutions. This financial backing not only encourages companies to adopt advanced technologies but also fosters collaboration between academia and industry. As a result, the Germany virtual engineering market is likely to benefit from increased investment and innovation, positioning the country as a leader in the field.

Advancements in Simulation Technologies

Advancements in simulation technologies are driving innovation within the Germany virtual engineering market. The development of sophisticated simulation software allows engineers to create highly accurate models of complex systems, which can be tested and optimized before physical implementation. In 2025, the simulation software market in Germany was estimated to be worth around 800 million euros, with a projected growth rate of 20% annually. These technologies enable companies to reduce prototyping costs and accelerate product development cycles. Moreover, the integration of virtual reality and augmented reality into simulation processes enhances user experience and facilitates better understanding of engineering concepts. As these technologies continue to evolve, they are likely to play a pivotal role in shaping the future of the Germany virtual engineering market.

Increased Collaboration Across Industries

Increased collaboration across various industries is emerging as a vital driver in the Germany virtual engineering market. Companies are recognizing the benefits of cross-industry partnerships to leverage expertise and share resources in developing innovative virtual engineering solutions. For example, collaborations between automotive manufacturers and software firms have led to the creation of advanced simulation tools that enhance vehicle design and testing. In 2025, around 60% of German companies reported engaging in collaborative projects focused on virtual engineering. This trend not only fosters innovation but also accelerates the adoption of best practices across sectors. As industries continue to converge, the Germany virtual engineering market is likely to experience enhanced growth driven by collaborative efforts.