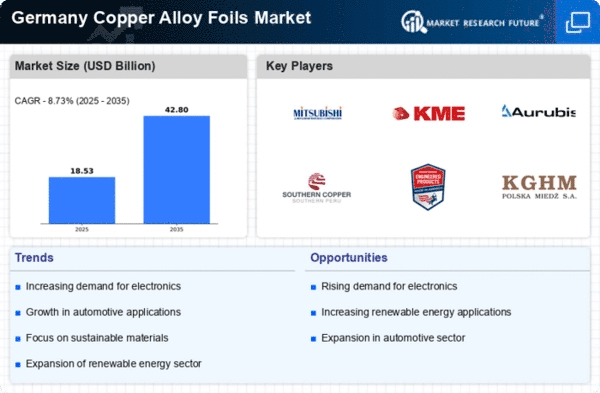

The copper alloy-foils market in Germany is characterized by a competitive landscape that is increasingly shaped by innovation, sustainability, and strategic partnerships. Key players such as Aurubis AG (Germany), KME Germany GmbH (Germany), and Mitsubishi Materials Corporation (Japan) are actively pursuing strategies that emphasize technological advancement and operational efficiency. Aurubis AG, for instance, focuses on sustainable production methods, which not only enhance their market position but also align with the growing demand for environmentally friendly materials. Meanwhile, KME Germany GmbH is leveraging its extensive manufacturing capabilities to optimize supply chains, thereby improving responsiveness to market fluctuations. Collectively, these strategies contribute to a dynamic competitive environment where adaptability and forward-thinking are paramount.In terms of business tactics, companies are increasingly localizing manufacturing to reduce lead times and enhance supply chain resilience. This approach appears to be particularly effective in a moderately fragmented market, where the collective influence of major players can significantly impact pricing and availability. The emphasis on supply chain optimization is evident as firms seek to mitigate risks associated with global disruptions, thereby ensuring a more stable market structure.

In October Aurubis AG (Germany) announced a partnership with a leading technology firm to develop advanced recycling processes for copper alloys. This strategic move is likely to enhance Aurubis's sustainability credentials while also reducing production costs, positioning the company favorably in a market that increasingly values eco-friendly practices. The collaboration may also lead to innovations that could redefine industry standards for recycling efficiency.

In September KME Germany GmbH (Germany) unveiled a new line of high-performance copper alloy foils designed for the electronics sector. This product launch not only reflects KME's commitment to innovation but also addresses the growing demand for specialized materials in high-tech applications. By focusing on niche markets, KME is likely to strengthen its competitive edge and capture a larger share of the market.

In August Mitsubishi Materials Corporation (Japan) expanded its production capacity in Germany, aiming to meet the rising demand for copper alloy foils in the automotive and electronics industries. This expansion is indicative of Mitsubishi's long-term strategy to enhance its market presence in Europe, potentially allowing the company to better serve its customers and respond to regional market dynamics.

As of November the competitive trends in the copper alloy-foils market are increasingly defined by digitalization, sustainability, and the integration of advanced technologies such as AI. Strategic alliances are becoming more prevalent, as companies recognize the need to collaborate in order to innovate and remain competitive. The shift from price-based competition to a focus on technological advancement and supply chain reliability is evident, suggesting that future differentiation will hinge on the ability to innovate and adapt to changing market demands.