Expansion of Industrial Applications

The FTIR Oil Condition Monitoring Market is witnessing an expansion of industrial applications, which is contributing to its growth. Various sectors, including automotive, aerospace, and manufacturing, are increasingly adopting FTIR technology for oil condition monitoring. This expansion is driven by the need for enhanced reliability and performance of machinery. Industries are recognizing that regular monitoring of oil conditions can lead to improved operational efficiency and reduced maintenance costs. As more sectors begin to implement FTIR solutions, the market is expected to experience significant growth. The versatility of FTIR technology allows it to be applied in diverse environments, making it a valuable tool for organizations aiming to optimize their maintenance practices. This broadening of applications is likely to play a crucial role in shaping the future of the FTIR Oil Condition Monitoring Market.

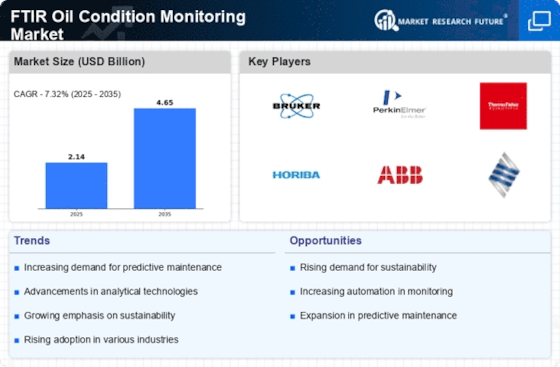

Rising Demand for Predictive Maintenance

The FTIR Oil Condition Monitoring Market is experiencing a notable increase in demand for predictive maintenance solutions. Industries are increasingly recognizing the value of monitoring oil conditions to prevent equipment failures and reduce downtime. This trend is driven by the need for operational efficiency and cost savings. According to recent data, predictive maintenance can reduce maintenance costs by up to 30% and increase equipment lifespan by 20%. As organizations strive to enhance their maintenance strategies, the adoption of FTIR technology is likely to grow, enabling real-time analysis of oil conditions and facilitating timely interventions. This shift towards predictive maintenance is expected to propel the FTIR Oil Condition Monitoring Market forward, as companies seek to leverage data-driven insights for improved asset management.

Regulatory Compliance and Safety Standards

The FTIR Oil Condition Monitoring Market is being propelled by stringent regulatory compliance and safety standards across various sectors. Industries are mandated to adhere to environmental regulations and safety protocols, which necessitate the monitoring of oil conditions to prevent hazardous incidents. The implementation of FTIR technology aids organizations in meeting these compliance requirements by providing accurate and timely data on oil quality. This is particularly relevant in sectors such as automotive and manufacturing, where the failure to comply can result in significant penalties. As regulations continue to evolve, the demand for FTIR oil condition monitoring solutions is expected to rise, driving growth in the market. Companies are likely to invest in FTIR systems to ensure compliance and enhance their safety measures, thereby contributing to the expansion of the FTIR Oil Condition Monitoring Market.

Technological Advancements in FTIR Systems

Technological advancements in FTIR systems are significantly influencing the FTIR Oil Condition Monitoring Market. Innovations in sensor technology, data analytics, and machine learning are enhancing the capabilities of FTIR systems, allowing for more accurate and rapid analysis of oil conditions. These advancements enable users to detect contaminants and degradation products in oils with greater precision. As a result, industries are increasingly adopting FTIR technology to ensure optimal performance of machinery and reduce the risk of failures. The market is projected to grow as these advanced systems become more accessible and affordable, thereby expanding their application across various sectors, including automotive, manufacturing, and energy. The integration of cutting-edge technologies into FTIR systems is likely to drive the FTIR Oil Condition Monitoring Market towards new heights.

Growing Awareness of Oil Quality Management

There is a growing awareness of the importance of oil quality management within the FTIR Oil Condition Monitoring Market. Organizations are increasingly recognizing that maintaining high oil quality is essential for the longevity and efficiency of machinery. This awareness is leading to a rise in the adoption of FTIR technology, which provides comprehensive insights into oil conditions. By monitoring oil quality, companies can identify potential issues before they escalate, thereby minimizing maintenance costs and improving operational efficiency. The market is likely to benefit from this trend, as more industries prioritize oil quality management as a critical component of their maintenance strategies. The emphasis on oil quality is expected to drive the demand for FTIR oil condition monitoring solutions, further solidifying the market's growth trajectory.