Increased Investment in R&D

Investment in research and development is a significant factor propelling the 3d machine-vision market. Companies in France are allocating substantial resources to innovate and enhance their machine-vision technologies. This trend is reflected in the estimated €200 million investment in R&D for vision systems in 2025. Such investments are aimed at developing more sophisticated algorithms and improving the overall performance of 3d machine-vision systems. As a result, the market is likely to witness the introduction of cutting-edge solutions that cater to diverse industrial needs, thereby fostering growth and competitiveness in the sector.

Advancements in Sensor Technology

Technological innovations in sensor capabilities are significantly impacting the 3d machine-vision market. The development of high-resolution cameras and advanced imaging sensors allows for more accurate and faster data capture. In France, the adoption of these technologies is expected to increase, with the market for imaging sensors projected to reach €150 million by 2026. Enhanced sensor technology enables industries to implement more sophisticated 3d machine-vision systems that can perform complex tasks such as real-time monitoring and analysis. This advancement not only improves operational efficiency but also opens new avenues for applications in sectors like robotics and automation, where precision is paramount.

Rising Demand for Quality Control

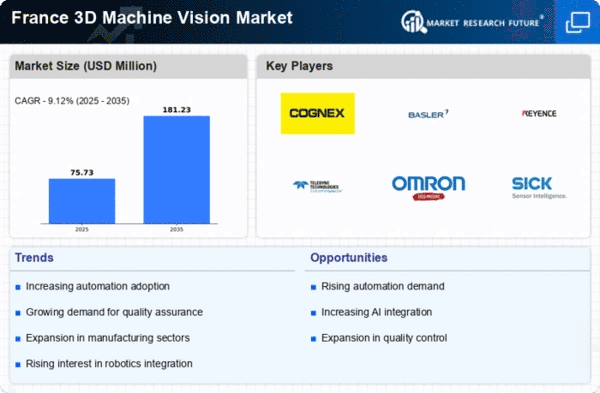

The increasing emphasis on quality assurance in manufacturing processes is driving the 3d machine-vision market. Industries such as automotive and electronics are adopting advanced inspection systems to ensure product quality and compliance with standards. In France, the market for quality control solutions is projected to grow at a CAGR of 8.5% from 2025 to 2030. This growth is attributed to the need for precision and accuracy in production lines, where 3d machine-vision systems can detect defects and anomalies that traditional methods may overlook. As manufacturers strive to enhance their competitive edge, the integration of 3D machine-vision technology becomes essential for maintaining high-quality standards and reducing waste, thereby contributing to the overall efficiency of production processes.

Growth of Robotics in Manufacturing

The integration of robotics in manufacturing processes is a key driver for the 3d machine-vision market. As industries in France increasingly adopt robotic systems for tasks such as assembly and packaging, the need for vision systems that can guide these robots becomes critical. The market for robotic automation is expected to grow by 12% annually, with 3d machine-vision systems playing a vital role in enhancing the capabilities of robots. These systems provide the necessary feedback for robots to perform tasks with high precision, thereby improving productivity and reducing operational costs. The synergy between robotics and 3d machine-vision technology is likely to redefine manufacturing processes in the coming years.

Regulatory Compliance and Safety Standards

The stringent regulatory environment in France is influencing the 3d machine-vision market. Manufacturers are increasingly required to comply with safety and quality standards, which necessitates the adoption of advanced inspection technologies. The market is expected to see a rise in demand for 3d machine-vision systems that can assist in meeting these regulatory requirements. Compliance with standards not only ensures product safety but also enhances brand reputation. As industries strive to adhere to these regulations, the integration of 3d machine-vision technology becomes a strategic imperative, driving growth in the market.