Rising Demand for Quality Control

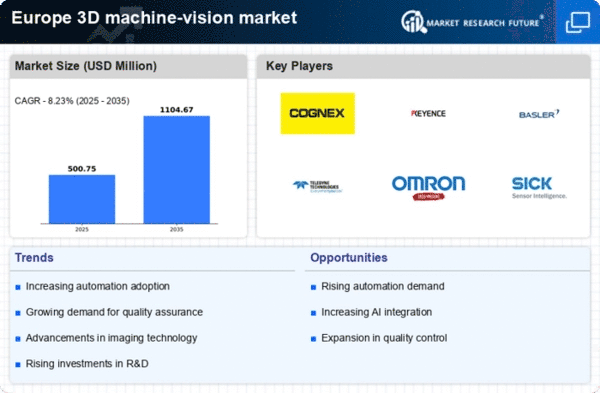

The increasing emphasis on quality assurance in manufacturing processes is a pivotal driver for the 3d machine-vision market in Europe. Industries such as automotive and electronics are adopting advanced inspection systems to ensure product integrity. The market for quality control solutions is projected to grow at a CAGR of 10% from 2025 to 2030, indicating a robust demand for 3d machine-vision technologies. This trend is further fueled by the need to minimize defects and enhance operational efficiency, as manufacturers strive to meet stringent quality standards. Consequently, the 3d machine-vision market is witnessing a surge in investments aimed at developing sophisticated imaging systems that can detect even the minutest discrepancies in products, thereby reinforcing the importance of quality control in competitive markets.

Growing Focus on Safety and Compliance

The heightened focus on safety and compliance regulations across various sectors is driving the 3d machine-vision market in Europe. Industries such as food and pharmaceuticals are under increasing scrutiny to adhere to safety standards, necessitating the implementation of reliable inspection systems. The market for safety compliance solutions is projected to grow at a CAGR of 8% through 2028, reflecting the urgency for companies to adopt technologies that ensure adherence to regulations. This trend indicates that the 3d machine-vision market is becoming increasingly vital in helping organizations meet compliance requirements while maintaining operational efficiency. As a result, investments in machine-vision systems that enhance safety protocols are likely to rise.

Expansion of E-commerce and Retail Automation

The rapid expansion of e-commerce and the subsequent need for retail automation are significant drivers for the 3d machine-vision market in Europe. As online shopping continues to grow, retailers are investing in automated systems to streamline operations and improve customer experience. The e-commerce sector is projected to reach €500 billion by 2026, prompting retailers to adopt advanced technologies, including 3d machine-vision systems, for inventory management and order fulfillment. This trend suggests that the 3d machine-vision market will play a crucial role in enhancing operational efficiency and accuracy in retail environments. Consequently, the demand for innovative vision solutions tailored to the needs of the e-commerce sector is likely to increase.

Technological Advancements in Imaging Systems

Technological innovations in imaging systems are significantly influencing the 3d machine-vision market in Europe. The advent of high-resolution cameras and advanced algorithms has enhanced the capabilities of machine-vision systems, allowing for more precise measurements and faster processing times. For instance, the integration of deep learning techniques is enabling systems to learn from data and improve their accuracy over time. This evolution is expected to drive the market growth, with projections indicating a potential increase in market size to €1.5 billion by 2027. As industries seek to leverage these advancements, the 3d machine-vision market is likely to experience a shift towards more automated and intelligent solutions, catering to the growing demands for efficiency and accuracy.

Increased Adoption of Robotics in Manufacturing

The growing integration of robotics in manufacturing processes is a crucial driver for the 3d machine-vision market in Europe. As industries increasingly automate their operations, the need for precise machine-vision systems to guide robotic applications becomes paramount. The market for robotic automation is expected to reach €10 billion by 2026, with a significant portion attributed to the incorporation of 3d machine-vision technologies. This trend suggests that manufacturers are recognizing the value of combining robotics with advanced vision systems to enhance productivity and reduce operational costs. Consequently, the 3d machine-vision market is likely to benefit from this synergy, as more companies invest in integrated solutions that optimize both robotic and vision capabilities.