Market Trends and Projections

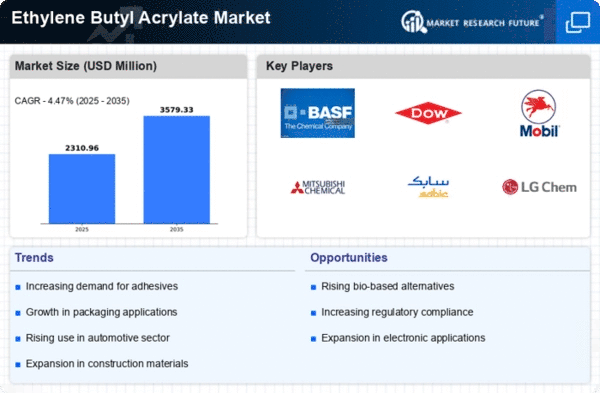

The Global Ethylene Butyl Acrylate Market Industry is characterized by various trends and projections that indicate its future trajectory. The market is expected to grow from 2.21 USD Billion in 2024 to 3.58 USD Billion by 2035, reflecting a robust CAGR of 4.49% from 2025 to 2035. This growth is driven by increasing demand across multiple sectors, including automotive, construction, and consumer goods. The evolving landscape of material science, coupled with a heightened focus on sustainability, suggests that ethylene butyl acrylate will play a pivotal role in future applications, further solidifying its position in the global market.

Growth in Automotive Applications

The automotive sector significantly influences the Global Ethylene Butyl Acrylate Market Industry, as manufacturers increasingly utilize ethylene butyl acrylate in various components. Its properties, such as excellent weather resistance and flexibility, make it suitable for applications like coatings, adhesives, and sealants in vehicles. As the automotive industry evolves, particularly with the rise of electric vehicles, the demand for lightweight and durable materials is anticipated to grow. This shift could contribute to the market's expansion, with projections indicating a market size of 3.58 USD Billion by 2035, underscoring the material's relevance in future automotive innovations.

Rising Demand in Adhesives and Sealants

The Global Ethylene Butyl Acrylate Market Industry experiences a notable increase in demand for adhesives and sealants, driven by their extensive applications in construction, automotive, and packaging sectors. As industries seek materials that offer superior adhesion and flexibility, ethylene butyl acrylate emerges as a preferred choice. In 2024, the market is projected to reach 2.21 USD Billion, reflecting the growing reliance on high-performance adhesives. This trend is likely to continue, as the construction industry alone is expected to expand, further propelling the demand for ethylene butyl acrylate-based products.

Expanding Applications in Consumer Goods

The Global Ethylene Butyl Acrylate Market Industry is experiencing an expansion in applications within consumer goods, including personal care products, textiles, and household items. Ethylene butyl acrylate's unique properties, such as flexibility and durability, make it an attractive choice for manufacturers seeking high-performance materials. As consumer preferences shift towards quality and functionality, the demand for ethylene butyl acrylate in these sectors is likely to rise. This trend not only supports the market's growth but also highlights the versatility of ethylene butyl acrylate in meeting diverse consumer needs.

Technological Advancements in Production

Technological advancements play a crucial role in shaping the Global Ethylene Butyl Acrylate Market Industry. Innovations in production processes enhance the efficiency and quality of ethylene butyl acrylate, leading to reduced costs and improved performance characteristics. For instance, advancements in polymerization techniques allow for better control over molecular weight and composition, resulting in tailored products for specific applications. As manufacturers adopt these technologies, the market is expected to benefit from increased production capacity and product diversity. This evolution may contribute to the overall growth trajectory of the market, aligning with the projected figures for the coming years.

Increasing Focus on Sustainable Materials

The Global Ethylene Butyl Acrylate Market Industry is witnessing a shift towards sustainable materials, as manufacturers and consumers alike prioritize eco-friendly options. Ethylene butyl acrylate, being a versatile polymer, can be formulated to meet stringent environmental regulations while maintaining performance. This trend is particularly evident in packaging applications, where biodegradable and recyclable materials are gaining traction. As companies strive to reduce their carbon footprint, the demand for sustainable alternatives is likely to bolster the market. The anticipated CAGR of 4.49% from 2025 to 2035 suggests a growing recognition of the importance of sustainability in material selection.