Market Growth Projections

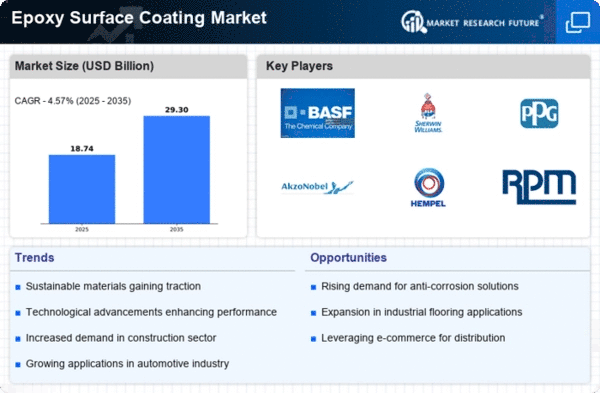

The Global Epoxy Surface Coating Market Industry is poised for substantial growth, with projections indicating a market size of 25 USD Billion in 2024 and an anticipated increase to 40 USD Billion by 2035. This growth trajectory suggests a compound annual growth rate of 4.37% from 2025 to 2035. Factors contributing to this expansion include rising demand across various sectors, technological advancements, and a shift towards sustainable practices. The market's evolution reflects broader trends in construction, automotive, and industrial applications, positioning epoxy coatings as a critical component in modern manufacturing and infrastructure development.

Expansion of Industrial Applications

The Global Epoxy Surface Coating Market Industry is witnessing an expansion in industrial applications, particularly in manufacturing and warehousing. Epoxy coatings are increasingly utilized for their excellent adhesion, chemical resistance, and ease of maintenance. Industries such as food and beverage, pharmaceuticals, and electronics are adopting epoxy solutions to meet stringent hygiene and safety standards. This trend is expected to contribute to a compound annual growth rate of 4.37% from 2025 to 2035, reflecting the growing recognition of epoxy coatings as essential for operational efficiency and compliance in various industrial settings.

Rising Demand in Construction Sector

The Global Epoxy Surface Coating Market Industry experiences a robust demand driven by the construction sector. As urbanization accelerates, the need for durable and aesthetically pleasing flooring solutions increases. Epoxy coatings are favored for their resistance to wear and tear, making them ideal for high-traffic areas. In 2024, the market is projected to reach 25 USD Billion, reflecting the growing preference for epoxy solutions in commercial and residential buildings. This trend indicates a shift towards sustainable construction practices, as epoxy coatings often contribute to energy efficiency and longevity, further solidifying their role in modern construction.

Environmental Regulations and Sustainability

The Global Epoxy Surface Coating Market Industry is increasingly shaped by stringent environmental regulations. Governments worldwide are promoting eco-friendly products, leading to a rise in demand for low-VOC and water-based epoxy coatings. These sustainable options align with global efforts to reduce carbon footprints and enhance indoor air quality. As a result, manufacturers are investing in research and development to create greener alternatives without compromising performance. This shift not only meets regulatory requirements but also appeals to environmentally conscious consumers, potentially expanding the market's reach and fostering innovation in product development.

Growth in Automotive and Aerospace Industries

The automotive and aerospace sectors are pivotal drivers of the Global Epoxy Surface Coating Market Industry. Epoxy coatings are essential for protecting vehicles and aircraft from corrosion, chemicals, and extreme weather conditions. As these industries evolve, the demand for high-performance coatings that enhance durability and aesthetics is likely to rise. With projections indicating a market growth to 40 USD Billion by 2035, the epoxy coating segment is positioned to benefit from increased production and innovation in vehicle and aircraft design. This trend underscores the importance of epoxy coatings in maintaining the integrity and longevity of critical components.

Technological Advancements in Coating Applications

Technological innovations significantly influence the Global Epoxy Surface Coating Market Industry. Advanced application techniques, such as spray and roller methods, enhance the efficiency and effectiveness of epoxy coatings. These advancements not only improve the quality of the finish but also reduce application time and labor costs. As manufacturers adopt new technologies, the market is likely to expand, catering to diverse industries including automotive, aerospace, and marine. The integration of smart coatings, which can respond to environmental changes, may further drive growth, positioning epoxy coatings as a versatile solution for various applications.