Expansion of End-Use Industries

The expansion of end-use industries, particularly in emerging economies, plays a pivotal role in shaping the Global Epoxy Paints and Coatings Market Industry. As urbanization accelerates, there is a corresponding increase in construction activities, leading to heightened demand for protective coatings. The automotive sector also contributes significantly, with manufacturers seeking advanced coatings to enhance vehicle durability and aesthetics. This trend is anticipated to propel the market to 45 USD Billion by 2035, as industries recognize the value of epoxy coatings in improving product longevity and performance.

Rising Demand for Durable Coatings

The Global Epoxy Paints and Coatings Market Industry experiences a surge in demand for durable coatings across various sectors, including automotive, construction, and marine. This trend is driven by the need for protective finishes that can withstand harsh environmental conditions. For instance, epoxy coatings are increasingly utilized in industrial flooring due to their resistance to chemicals and abrasion. As a result, the market is projected to reach 25 USD Billion in 2024, reflecting a growing preference for long-lasting solutions. The durability of epoxy paints not only enhances the aesthetic appeal but also extends the lifespan of surfaces, thereby reducing maintenance costs.

Growing Awareness of Environmental Sustainability

There is a notable shift towards environmentally sustainable practices within the Global Epoxy Paints and Coatings Market Industry. Consumers and businesses alike are increasingly prioritizing eco-friendly products that minimize environmental impact. This awareness drives manufacturers to develop low-VOC and water-based epoxy coatings that align with sustainability goals. As regulations become more stringent, the demand for such products is likely to rise, further influencing market dynamics. The industry's commitment to sustainability not only meets consumer expectations but also positions it favorably in a competitive landscape.

Increased Investment in Infrastructure Development

Increased investment in infrastructure development globally serves as a catalyst for the Global Epoxy Paints and Coatings Market Industry. Governments and private entities are allocating substantial resources towards building and renovating infrastructure, including roads, bridges, and public facilities. Epoxy coatings are favored for their protective qualities, which enhance the durability of infrastructure projects. This trend is expected to sustain market growth, as the demand for high-performance coatings continues to rise in tandem with infrastructure initiatives. The strategic focus on infrastructure development underscores the importance of epoxy coatings in ensuring long-lasting and resilient structures.

Technological Advancements in Coating Formulations

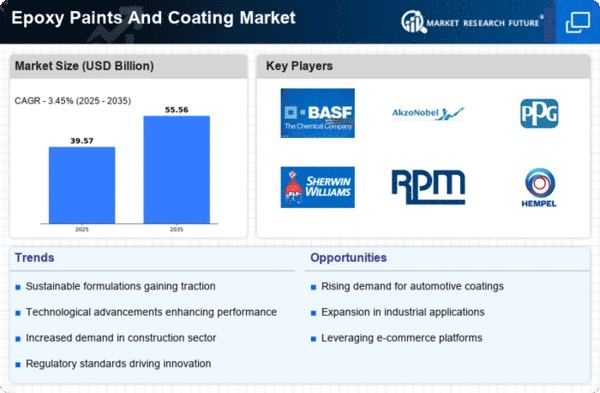

Innovations in coating formulations significantly influence the Global Epoxy Paints and Coatings Market Industry. Manufacturers are increasingly investing in research and development to create advanced epoxy formulations that offer improved performance characteristics, such as faster curing times and enhanced adhesion properties. These advancements enable the production of eco-friendly epoxy paints that comply with stringent environmental regulations. Consequently, the market is expected to grow at a CAGR of 5.49% from 2025 to 2035, driven by the introduction of high-performance coatings that meet the evolving needs of consumers and industries alike.