Growing Demand in Construction Sector

The Global Epoxy Silanes Market Industry is experiencing a surge in demand driven by the construction sector. Epoxy silanes are increasingly utilized in adhesives, sealants, and coatings, which are essential for modern construction projects. The rising trend towards sustainable building materials and energy-efficient structures further propels this demand. For instance, epoxy silanes enhance the durability and performance of construction materials, making them more appealing to builders and architects. As the construction industry continues to expand, particularly in emerging economies, the market for epoxy silanes is projected to grow significantly, contributing to the overall market value of 1250 USD Million in 2024.

Rising Automotive Industry Applications

The automotive industry is a significant driver for the Global Epoxy Silanes Market Industry, as these compounds are increasingly used in vehicle manufacturing. Epoxy silanes are essential in enhancing the adhesion properties of coatings and sealants used in automobiles, contributing to improved durability and performance. With the automotive sector focusing on lightweight materials and fuel efficiency, the demand for epoxy silanes is likely to increase. The integration of epoxy silanes in electric vehicles and advanced automotive technologies further underscores their importance. This growing application in the automotive sector is expected to support a compound annual growth rate of 7.43% from 2025 to 2035.

Technological Advancements in Manufacturing

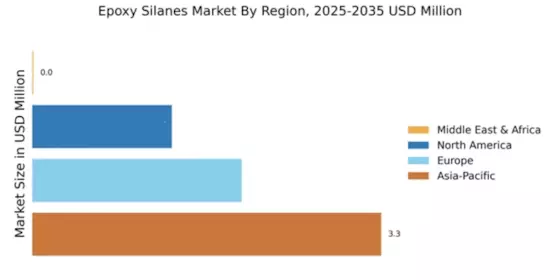

Technological advancements in the production of epoxy silanes are playing a crucial role in the Global Epoxy Silanes Market Industry. Innovations in synthesis methods and formulations are leading to the development of more efficient and effective products. For example, the introduction of new catalysts and processes has improved the performance characteristics of epoxy silanes, making them more versatile for various applications. These advancements not only enhance product quality but also reduce production costs, thereby increasing market competitiveness. As manufacturers adopt these technologies, the market is expected to witness a robust growth trajectory, potentially reaching 2750 USD Million by 2035.

Environmental Regulations and Sustainability Trends

Environmental regulations and sustainability trends are shaping the Global Epoxy Silanes Market Industry. As governments worldwide implement stricter regulations on chemical emissions and waste management, manufacturers are compelled to adopt more sustainable practices. Epoxy silanes, known for their low environmental impact and high efficiency, are becoming a preferred choice in various applications. The shift towards eco-friendly materials is not only a regulatory requirement but also a market demand, as consumers increasingly favor sustainable products. This trend is likely to drive the growth of the epoxy silanes market, aligning with global sustainability goals and enhancing the industry's reputation.

Expansion of Electronics and Semiconductor Industries

The expansion of the electronics and semiconductor industries is significantly influencing the Global Epoxy Silanes Market Industry. Epoxy silanes are utilized in the manufacturing of electronic components, including circuit boards and semiconductor devices, due to their excellent adhesive properties and thermal stability. As the demand for consumer electronics continues to rise, driven by technological advancements and increased connectivity, the need for high-performance materials like epoxy silanes becomes more pronounced. This trend is expected to bolster the market, as manufacturers seek to enhance product reliability and performance in increasingly compact electronic devices.