Growth of the Home Appliance Sector

The expansion of the home appliance sector is a significant driver for the Electrical Appliance Coating Market. As urbanization continues to rise, there is an increasing demand for modern home appliances that enhance convenience and efficiency. This trend is particularly evident in emerging markets, where rising disposable incomes are leading to higher spending on household goods. The home appliance market is anticipated to grow at a rate of 8% annually, which directly correlates with the demand for innovative coatings that improve product performance and aesthetics. Manufacturers are increasingly focusing on developing coatings that not only provide protection but also contribute to the overall design and functionality of appliances. This growth in the home appliance sector is likely to bolster the Electrical Appliance Coating Market as companies strive to meet consumer expectations.

Regulatory Standards and Compliance

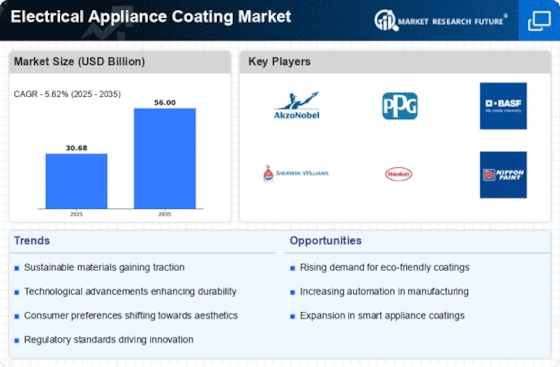

Regulatory standards and compliance requirements are increasingly influencing the Electrical Appliance Coating Market. Governments worldwide are implementing stringent regulations regarding the safety and environmental impact of coatings used in electrical appliances. These regulations often mandate the use of low-VOC and eco-friendly materials, pushing manufacturers to adapt their coating processes. Compliance with these standards not only ensures product safety but also enhances brand reputation among environmentally conscious consumers. As a result, the demand for compliant coatings is expected to rise, driving innovation within the Electrical Appliance Coating Market. Companies that proactively align their products with these regulations are likely to gain a competitive edge, further stimulating market growth.

Consumer Preference for Aesthetic Appeal

Consumer preference for aesthetic appeal in electrical appliances is a notable driver for the Electrical Appliance Coating Market. As appliances become integral to home decor, manufacturers are increasingly focusing on the visual aspects of their products. Coatings that offer a variety of colors, finishes, and textures are in high demand, allowing consumers to personalize their appliances to match their interior design. This trend is particularly pronounced among younger consumers who prioritize style alongside functionality. The market for decorative coatings is projected to grow significantly, indicating a shift in consumer behavior. As manufacturers respond to these preferences, the Electrical Appliance Coating Market is likely to expand, driven by the need for innovative and visually appealing coating solutions.

Rising Demand for Energy-Efficient Appliances

The increasing emphasis on energy efficiency in appliances is a pivotal driver for the Electrical Appliance Coating Market. As consumers become more environmentally conscious, manufacturers are compelled to innovate and produce energy-efficient products. Coatings that enhance thermal insulation and reduce energy consumption are gaining traction. According to recent data, the energy-efficient appliance market is projected to grow at a compound annual growth rate of 10% over the next five years. This trend not only aligns with global sustainability goals but also propels the demand for specialized coatings that can withstand higher temperatures and improve appliance performance. Consequently, the Electrical Appliance Coating Market is likely to experience significant growth as manufacturers seek to meet these evolving consumer preferences.

Technological Innovations in Coating Applications

Technological advancements in coating applications are transforming the Electrical Appliance Coating Market. Innovations such as nanotechnology and advanced polymer formulations are enabling the development of coatings that offer superior durability, resistance to wear, and enhanced aesthetic appeal. These advancements allow manufacturers to create appliances that not only perform better but also have a longer lifespan. For instance, the introduction of self-cleaning and anti-fingerprint coatings is becoming increasingly popular among appliance manufacturers. As these technologies continue to evolve, they are expected to drive the demand for specialized coatings, thereby expanding the Electrical Appliance Coating Market. The integration of smart technologies into appliances further necessitates the use of advanced coatings that can protect sensitive components from environmental factors.