Increasing Regulatory Standards

The increasing regulatory standards across various sectors are driving the Elastomers for Valve Soft Seat Market. Governments and regulatory bodies are implementing stringent guidelines to ensure safety and environmental compliance in industrial operations. This has led to a heightened focus on the materials used in valve applications, particularly in sectors such as pharmaceuticals and food processing. Elastomers that meet these regulatory requirements are becoming essential for manufacturers aiming to maintain compliance and avoid penalties. The market is expected to see a surge in demand for elastomers that are not only high-performing but also compliant with safety standards. This trend indicates a growing opportunity for the Elastomers for Valve Soft Seat Market, as companies seek to align their products with evolving regulations and consumer expectations.

Expansion of End-User Industries

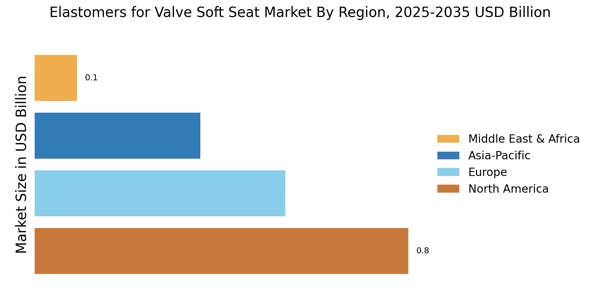

The expansion of end-user industries is a crucial driver for the Elastomers for Valve Soft Seat Market. Sectors such as automotive, aerospace, and energy are experiencing significant growth, leading to an increased need for reliable valve components. As these industries expand, the demand for elastomers that can provide effective sealing and performance in valve applications is likely to rise. For instance, the automotive industry is projected to grow at a rate of 4% annually, which will subsequently boost the demand for elastomeric valve soft seats. This expansion creates a favorable environment for the Elastomers for Valve Soft Seat Market, as manufacturers strive to meet the evolving needs of their clients. The interplay between industry growth and elastomer demand suggests a promising outlook for the market.

Rising Demand for Durable Materials

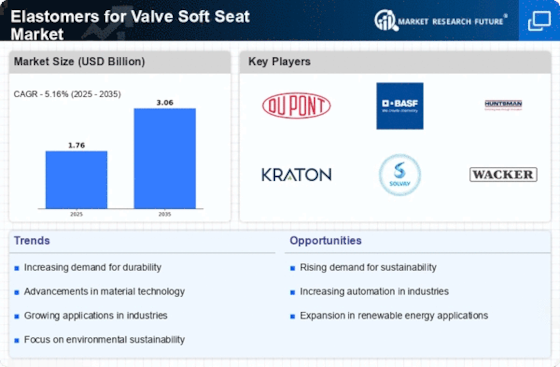

The increasing demand for durable materials in various industries is a primary driver for the Elastomers for Valve Soft Seat Market. Industries such as oil and gas, water treatment, and chemical processing require materials that can withstand harsh conditions. Elastomers, known for their resilience and flexibility, are increasingly favored for valve soft seats. The market for elastomers is projected to grow at a compound annual growth rate of approximately 5.5% over the next few years, indicating a robust demand. This trend is likely to enhance the adoption of elastomers in valve applications, as manufacturers seek to improve the longevity and reliability of their products. Consequently, the Elastomers for Valve Soft Seat Market is expected to benefit from this rising demand, as companies prioritize performance and durability in their valve components.

Technological Innovations in Manufacturing

Technological innovations in manufacturing processes are significantly influencing the Elastomers for Valve Soft Seat Market. Advances in polymer chemistry and processing techniques have led to the development of new elastomer formulations that offer enhanced performance characteristics. For instance, the introduction of high-performance elastomers with superior chemical resistance and temperature stability is reshaping the market landscape. These innovations not only improve the functionality of valve soft seats but also reduce production costs, making them more accessible to manufacturers. As a result, the market is witnessing a shift towards more advanced elastomer solutions, which are likely to drive growth in the Elastomers for Valve Soft Seat Market. The integration of automation and smart manufacturing technologies further supports this trend, enabling companies to produce high-quality elastomer products efficiently.

Focus on Sustainability and Eco-Friendly Solutions

The focus on sustainability and eco-friendly solutions is increasingly shaping the Elastomers for Valve Soft Seat Market. As industries strive to reduce their environmental footprint, there is a growing demand for elastomers that are recyclable and produced through sustainable practices. Manufacturers are responding by developing bio-based elastomers and other environmentally friendly materials that align with sustainability goals. This shift not only caters to consumer preferences but also helps companies comply with environmental regulations. The market for sustainable elastomers is expected to grow, with projections indicating a potential increase of 6% in the coming years. This trend highlights the importance of sustainability in the Elastomers for Valve Soft Seat Market, as companies seek to innovate and adapt to changing market dynamics.