Rising Demand in Construction Sector

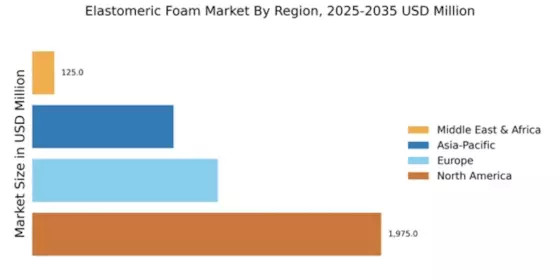

The Global Elastomeric Foam Market Industry experiences a notable surge in demand driven by the construction sector. As urbanization accelerates, the need for insulation materials in residential and commercial buildings increases. Elastomeric foam is favored for its thermal insulation properties, contributing to energy efficiency. In 2024, the market is projected to reach 3.95 USD Billion, reflecting the growing emphasis on sustainable building practices. The integration of elastomeric foam in HVAC systems further enhances its appeal, as it helps reduce energy consumption. This trend is expected to continue, positioning elastomeric foam as a vital component in modern construction.

Growing Awareness of Energy Efficiency

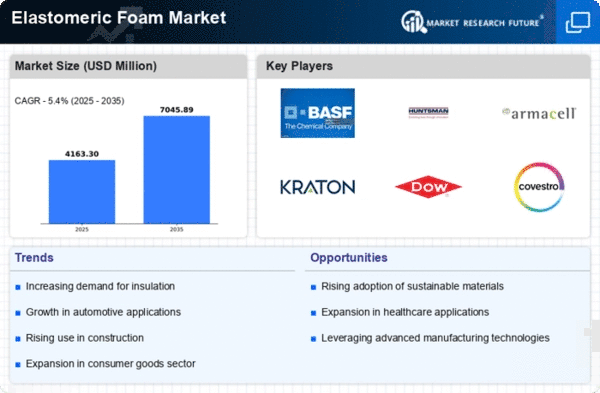

The Global Elastomeric Foam Market Industry is significantly influenced by the increasing awareness of energy efficiency among consumers and industries. As energy costs rise, there is a pressing need for materials that enhance insulation and reduce energy consumption. Elastomeric foam, known for its superior thermal performance, plays a crucial role in achieving energy-efficient solutions. This awareness is reflected in the projected growth of the market, expected to reach 7.04 USD Billion by 2035. Industries are increasingly adopting elastomeric foam in their products, aligning with global sustainability goals and regulations aimed at reducing carbon footprints.

Technological Advancements in Manufacturing

Technological advancements in manufacturing processes are propelling the Global Elastomeric Foam Market Industry forward. Innovations such as improved formulations and production techniques enhance the performance characteristics of elastomeric foam, making it more versatile and efficient. These advancements enable manufacturers to produce foam with tailored properties, catering to diverse applications across various sectors, including automotive, aerospace, and construction. As a result, the market is expected to witness a compound annual growth rate of 5.39% from 2025 to 2035. This growth is indicative of the industry's ability to adapt and innovate in response to evolving market demands.

Increased Application in Automotive Industry

The Global Elastomeric Foam Market Industry is experiencing growth due to its increased application in the automotive sector. As manufacturers strive for lightweight materials that enhance fuel efficiency, elastomeric foam emerges as a favorable option. Its properties, such as sound insulation and vibration dampening, make it ideal for automotive interiors and components. The automotive industry's shift towards electric vehicles further amplifies the demand for elastomeric foam, as these vehicles require advanced insulation materials. This trend positions elastomeric foam as a critical material in the evolving automotive landscape, contributing to the overall growth of the market.

Regulatory Support for Sustainable Materials

Regulatory support for sustainable materials is a driving force in the Global Elastomeric Foam Market Industry. Governments worldwide are implementing policies that promote the use of eco-friendly materials in construction and manufacturing. Elastomeric foam, with its recyclable properties and energy-efficient characteristics, aligns well with these regulations. This support encourages industries to adopt elastomeric foam as a viable alternative to traditional materials, fostering market growth. As sustainability becomes a priority, the demand for elastomeric foam is likely to increase, reflecting a broader trend towards environmentally responsible practices across various sectors.