Advancements in Robotics Technology

Technological advancements play a pivotal role in shaping the Dual-Arm Robot Market. Innovations in artificial intelligence, machine learning, and sensor technologies are enabling dual-arm robots to perform complex tasks with greater autonomy and efficiency. For instance, the introduction of collaborative robots, or cobots, allows dual-arm robots to work alongside human operators safely. This trend is expected to expand the application range of dual-arm robots, particularly in sectors like logistics and assembly. Market data indicates that the robotics technology sector is anticipated to reach a valuation of over 200 billion by 2026, suggesting a robust growth trajectory. As these technologies continue to evolve, the capabilities of dual-arm robots will likely expand, further driving their adoption across various industries.

Increased Focus on Workplace Safety

The emphasis on workplace safety is becoming increasingly pronounced within the Dual-Arm Robot Market. As industries strive to minimize workplace accidents and enhance safety valve, the integration of dual-arm robots is seen as a viable solution. These robots can undertake hazardous tasks, thereby reducing the risk of injury to human workers. The market for safety solutions in industrial settings is projected to grow significantly, with estimates suggesting a potential increase of 8% annually. This trend indicates a growing recognition of the benefits that dual-arm robots can bring to safety protocols. Furthermore, regulatory bodies are likely to encourage the adoption of robotic solutions, which could further bolster the dual-arm robot market as companies seek to comply with safety standards.

Expansion of E-commerce and Logistics

The expansion of e-commerce and logistics sectors is significantly influencing the Dual-Arm Robot Market. As online shopping continues to grow, the demand for efficient warehousing and order fulfillment solutions is rising. Dual-arm robots are increasingly being utilized in these environments to automate picking, packing, and sorting processes. Market data reveals that the e-commerce sector is projected to grow at a rate of 15% annually, which is likely to drive the need for advanced robotic solutions. This growth presents a substantial opportunity for dual-arm robots to enhance operational efficiency in logistics. As companies strive to meet consumer demands for faster delivery times, the integration of dual-arm robots into supply chains is expected to become more prevalent.

Rising Demand for Precision Engineering

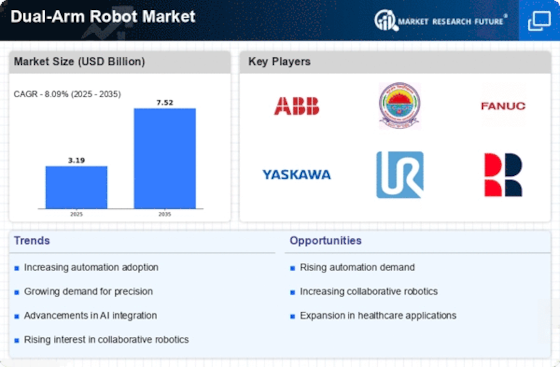

The Dual-Arm Robot Market is experiencing a notable surge in demand for precision engineering across various sectors. Industries such as automotive and electronics are increasingly adopting dual-arm robots to enhance manufacturing processes. These robots offer improved accuracy and efficiency, which are critical in high-stakes environments. According to recent data, the market for precision engineering is projected to grow at a compound annual growth rate of approximately 7% over the next five years. This growth is likely to drive investments in dual-arm robotics, as manufacturers seek to optimize production lines and reduce waste. The integration of advanced sensors and AI technologies further enhances the capabilities of dual-arm robots, making them indispensable in achieving high-quality standards in production.

Growing Investment in Automation Solutions

Investment in automation solutions is a key driver for the Dual-Arm Robot Market. As companies seek to enhance productivity and reduce operational costs, the adoption of dual-arm robots is becoming more prevalent. Industries such as manufacturing, logistics, and healthcare are increasingly allocating budgets towards automation technologies. Recent market analysis suggests that the automation sector is expected to witness a growth rate of around 10% over the next few years. This trend indicates a strong commitment from businesses to integrate advanced robotic solutions into their operations. The potential for dual-arm robots to streamline processes and improve efficiency is likely to attract further investments, thereby propelling the market forward.