North America : Market Leader in Dairy Services

North America leads the Dairy Processing Equipment Maintenance Services Market with a share of 1.25B. The growth is driven by increasing dairy production, stringent food safety regulations, and technological advancements in equipment. The demand for efficient maintenance services is rising as dairy processors seek to enhance productivity and reduce downtime. Regulatory support for sustainable practices further fuels market expansion.

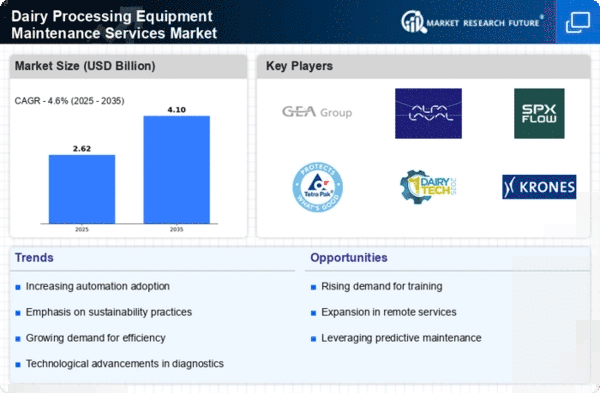

The U.S. stands as the largest market, with key players like GEA Group, SPX Flow, and Tetra Pak dominating the landscape. The competitive environment is characterized by innovation and strategic partnerships, ensuring high service quality. Canada also contributes significantly, focusing on modernization and compliance with health standards. Overall, the region's robust infrastructure supports a thriving maintenance services sector.

Europe : Emerging Market with Growth Potential

Europe's Dairy Processing Equipment Maintenance Services Market is valued at 0.75B, driven by increasing consumer demand for dairy products and stringent EU regulations on food safety and quality. The region is witnessing a shift towards automation and smart technologies, enhancing operational efficiency. Regulatory frameworks encourage investments in maintenance services, ensuring compliance with health and safety standards.

Germany and France are the leading countries in this market, with major players like Alfa Laval and Krones AG establishing a strong presence. The competitive landscape is marked by innovation and sustainability initiatives, as companies strive to meet evolving consumer preferences. The focus on reducing environmental impact is shaping service offerings, making Europe a dynamic market for dairy processing services.

Asia-Pacific : Rapidly Growing Dairy Sector

Asia-Pacific's Dairy Processing Equipment Maintenance Services Market is valued at 0.4B, reflecting rapid growth driven by rising dairy consumption and production. Countries like India and China are experiencing significant demand for maintenance services as they expand their dairy processing capabilities. The region's focus on improving food safety and quality standards is a key growth driver, supported by government initiatives.

India is a major player, with local companies like Dairy Tech gaining traction alongside international firms. The competitive landscape is evolving, with an increasing number of players entering the market to meet the growing demand. The region's diverse dairy sector presents opportunities for innovation and service differentiation, positioning Asia-Pacific as a vital market for dairy processing services.

Middle East and Africa : Untapped Market Potential

The Middle East and Africa's Dairy Processing Equipment Maintenance Services Market is valued at 0.1B, representing significant untapped potential. The region is witnessing a gradual increase in dairy consumption, driven by population growth and urbanization. However, the market is still in its infancy, with limited infrastructure and service availability. Regulatory frameworks are beginning to evolve, promoting food safety and quality standards.

Countries like South Africa and Kenya are leading the way, with local players starting to emerge in the maintenance services sector. The competitive landscape is characterized by a mix of established companies and new entrants, focusing on building capabilities to meet local demand. As the dairy sector develops, opportunities for growth in maintenance services will expand, making this region a future focal point for investment.