Growing E-commerce Sector

The Conveyor Monitoring Market is significantly impacted by the rapid expansion of the e-commerce sector. As online shopping continues to gain traction, logistics and warehousing operations are under pressure to optimize their supply chains. Conveyor systems play a crucial role in facilitating efficient order fulfillment and inventory management. Consequently, the demand for advanced conveyor monitoring solutions is on the rise, as companies seek to enhance their operational capabilities. Recent statistics indicate that the e-commerce market is projected to grow at a CAGR of around 14% over the next five years. This growth presents a substantial opportunity for the Conveyor Monitoring Market, as businesses increasingly invest in technologies that ensure seamless operations and minimize disruptions.

Rising Demand for Automation

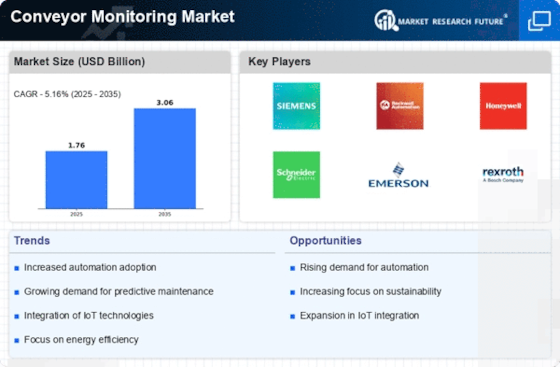

The Conveyor Monitoring Market experiences a notable surge in demand for automation across various sectors, including manufacturing, logistics, and food processing. As industries strive for enhanced efficiency and reduced operational costs, the integration of automated conveyor systems becomes increasingly prevalent. According to recent data, the automation market is projected to grow at a compound annual growth rate (CAGR) of approximately 10% over the next five years. This trend indicates a strong inclination towards automated solutions, which necessitate advanced monitoring systems to ensure optimal performance and reliability. Consequently, the Conveyor Monitoring Market is poised to benefit from this shift, as companies seek to implement sophisticated monitoring technologies that can provide real-time insights and predictive analytics, thereby minimizing downtime and maximizing productivity.

Emphasis on Energy Efficiency

The Conveyor Monitoring Market is increasingly shaped by the growing emphasis on energy efficiency within industrial operations. Organizations are recognizing the importance of reducing energy consumption to lower operational costs and minimize environmental impact. As a result, there is a rising demand for conveyor monitoring solutions that can provide insights into energy usage and identify areas for improvement. Technologies that enable real-time monitoring of energy consumption are becoming essential for companies aiming to enhance their sustainability initiatives. Market analysis indicates that energy-efficient conveyor systems can reduce energy costs by up to 30%. This trend underscores the potential for the Conveyor Monitoring Market to thrive as businesses prioritize energy efficiency and sustainability in their operations.

Increased Focus on Safety Regulations

The Conveyor Monitoring Market is significantly influenced by the heightened emphasis on safety regulations across various sectors. Regulatory bodies are increasingly mandating stringent safety standards to mitigate workplace hazards associated with conveyor systems. This regulatory landscape compels organizations to invest in advanced monitoring solutions that can detect potential failures and ensure compliance with safety protocols. For instance, the implementation of real-time monitoring systems can help identify anomalies and prevent accidents, thereby safeguarding employees and assets. As a result, the Conveyor Monitoring Market is likely to witness a robust growth trajectory, driven by the necessity for compliance and the desire to foster a safer working environment.

Technological Advancements in Monitoring Solutions

The Conveyor Monitoring Market is experiencing a transformative phase due to rapid technological advancements in monitoring solutions. Innovations such as artificial intelligence, machine learning, and advanced sensor technologies are revolutionizing the way conveyor systems are monitored and managed. These technologies enable predictive maintenance, allowing organizations to anticipate failures before they occur, thus reducing downtime and maintenance costs. Market data suggests that the adoption of AI-driven monitoring solutions is expected to increase by over 15% in the coming years. This trend indicates a growing recognition of the value of sophisticated monitoring systems in enhancing operational efficiency and reliability within the Conveyor Monitoring Market.