Expansion of Application Areas

The Constrained Layer Damping Market is experiencing an expansion of application areas, which is contributing to its growth. Traditionally utilized in automotive and aerospace applications, constrained layer damping solutions are now being adopted in diverse sectors such as construction, consumer electronics, and industrial machinery. This diversification is driven by the increasing need for effective noise and vibration control in various environments. For instance, the construction industry is increasingly using constrained layer damping materials in building designs to enhance occupant comfort and meet acoustic performance standards. Additionally, consumer electronics manufacturers are incorporating these materials to improve product durability and user experience. This broadening of application areas suggests that the constrained layer damping market is poised for continued growth as new opportunities emerge across different industries.

Regulatory Compliance and Standards

The Constrained Layer Damping Market is significantly influenced by regulatory compliance and standards aimed at reducing noise pollution and enhancing safety. Governments and regulatory bodies are increasingly implementing stringent guidelines that mandate the use of effective damping solutions in various applications. For instance, the automotive industry faces regulations that require manufacturers to limit noise emissions, thereby driving the adoption of constrained layer damping materials. Additionally, the aerospace sector is subject to rigorous safety standards that necessitate the use of advanced damping technologies to mitigate vibrations. This regulatory landscape is likely to propel the growth of the constrained layer damping market, as companies invest in compliant solutions to meet these requirements and avoid potential penalties.

Rising Demand for Lightweight Materials

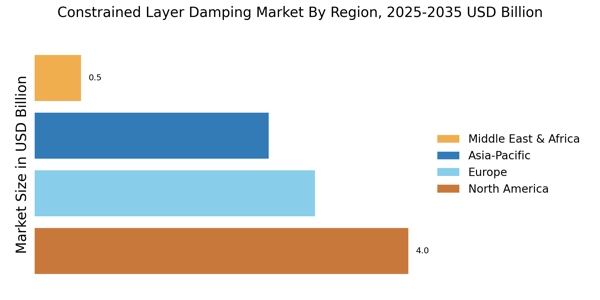

The Constrained Layer Damping Market is benefiting from the rising demand for lightweight materials, particularly in the automotive and aerospace sectors. As manufacturers strive to improve fuel efficiency and reduce emissions, there is a growing emphasis on the use of lightweight materials that do not compromise performance. Constrained layer damping materials, known for their effective vibration and noise reduction properties, are increasingly being integrated into lightweight structures. This trend is supported by data indicating that The Constrained Layer Damping Market is expected to grow significantly in the coming years. Consequently, the constrained layer damping market is likely to expand as manufacturers seek to incorporate these materials into their designs, thereby enhancing overall product performance while adhering to sustainability goals.

Growing Awareness of Noise and Vibration Control

The Constrained Layer Damping Market is witnessing an increase in awareness regarding noise and vibration control across multiple sectors. Industries such as automotive, aerospace, and construction are increasingly recognizing the detrimental effects of excessive noise and vibrations on both equipment performance and human health. This growing awareness is driving demand for effective damping solutions, as companies seek to enhance product quality and comply with stringent regulations regarding noise emissions. According to recent data, the automotive sector alone is projected to account for a substantial share of the constrained layer damping market, as manufacturers strive to improve passenger comfort and vehicle performance. This trend suggests that the market for constrained layer damping solutions is likely to expand as industries prioritize noise reduction and vibration control.

Technological Advancements in Manufacturing Processes

The Constrained Layer Damping Market is experiencing a notable transformation due to advancements in manufacturing processes. Innovations such as 3D printing and automated production techniques are enhancing the efficiency and precision of constrained layer damping materials. These technologies allow for the creation of complex geometries and tailored damping solutions that were previously unattainable. As a result, manufacturers can produce high-quality damping materials at a lower cost, which is likely to drive market growth. Furthermore, the integration of smart materials into constrained layer damping systems is emerging, potentially offering enhanced performance characteristics. This trend indicates a shift towards more sophisticated damping solutions, which could attract a broader range of applications across various sectors, including automotive and aerospace.