Rising Demand for Metallurgical Coke

The increasing demand for metallurgical coke, primarily used in steelmaking, is a key driver for the Coke Oven Battery Market. As steel production ramps up, the need for high-quality coke becomes paramount. Recent data indicates that the consumption of metallurgical coke is projected to grow at a rate of 4% per year, reflecting the ongoing expansion of the steel industry. This trend suggests that coke producers must enhance their production capabilities to meet the rising demand. Consequently, the Coke Oven Battery Market is likely to experience growth as companies strive to supply the necessary quantities of metallurgical coke to support steel manufacturing.

Increasing Demand for Steel Production

The demand for steel continues to rise, driven by various sectors such as construction, automotive, and manufacturing. The Coke Oven Battery Market plays a crucial role in steel production, as coke is a primary input in the blast furnace process. In recent years, the steel production capacity has expanded, with estimates suggesting a growth rate of approximately 3% annually. This trend indicates a robust need for coke, thereby propelling the Coke Oven Battery Market forward. As countries invest in infrastructure and industrial projects, the reliance on coke for steelmaking is likely to increase, further solidifying the market's position in the global economy.

Technological Innovations in Coke Production

Technological advancements are reshaping the Coke Oven Battery Market, with innovations aimed at improving efficiency and reducing costs. The introduction of new processes, such as non-recovery coke ovens and heat recovery systems, has the potential to enhance productivity while minimizing waste. These technologies not only optimize the production process but also align with sustainability goals by reducing energy consumption. As the industry embraces these innovations, it is likely to witness a shift in operational practices, which could lead to a more competitive landscape in the Coke Oven Battery Market. Companies that invest in research and development may find themselves at the forefront of this transformation.

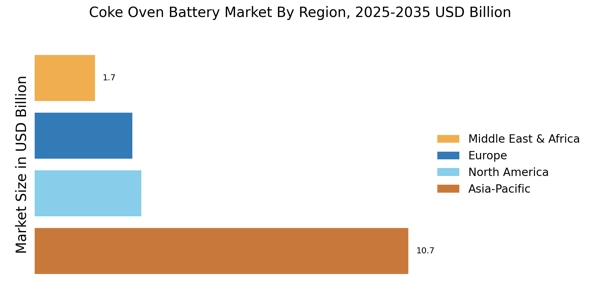

Emerging Economies and Infrastructure Development

Emerging economies are witnessing rapid infrastructure development, which is significantly impacting the Coke Oven Battery Market. As these countries invest in transportation, housing, and industrial facilities, the demand for steel and, consequently, coke is expected to surge. The construction sector, in particular, is a major consumer of steel, driving the need for metallurgical coke. Reports indicate that infrastructure spending in emerging markets could increase by 5% annually, creating a favorable environment for the Coke Oven Battery Market. This growth presents opportunities for coke producers to expand their operations and cater to the burgeoning demand in these regions.

Regulatory Compliance and Environmental Standards

The Coke Oven Battery Market is significantly influenced by stringent environmental regulations aimed at reducing emissions and promoting cleaner production methods. Governments worldwide are implementing policies that require coke producers to adopt advanced technologies to minimize their environmental footprint. Compliance with these regulations often necessitates investment in modern coke oven technologies, which can enhance efficiency and reduce harmful emissions. As a result, companies that prioritize sustainability and adhere to these regulations may gain a competitive edge in the Coke Oven Battery Market, potentially leading to increased market share and profitability.