Expansion of End-Use Industries

The expansion of end-use industries is a critical driver for the CO Polyester Ether Elastomers COPE Market. Sectors such as healthcare, consumer goods, and electronics are increasingly incorporating COPEs into their products due to their versatility and performance characteristics. In healthcare, COPEs are utilized in medical devices and packaging, where biocompatibility and flexibility are essential. The consumer goods sector is also leveraging COPEs for applications in soft-touch coatings and flexible packaging. As these industries continue to grow, the demand for COPEs is expected to rise correspondingly, with market analysts predicting a growth rate of around 5% annually. This expansion underscores the importance of COPEs in meeting the diverse needs of various applications across multiple sectors.

Growth in the Automotive Sector

The automotive sector plays a pivotal role in driving the CO Polyester Ether Elastomers COPE Market. With the ongoing shift towards electric vehicles (EVs) and hybrid models, there is a growing need for materials that can withstand higher temperatures and provide superior performance. COPEs are increasingly utilized in automotive applications due to their excellent thermal stability and resistance to chemicals. The automotive industry is projected to witness a substantial increase in the use of COPEs, with estimates indicating a market growth rate of approximately 6% annually. This growth is fueled by the demand for innovative materials that enhance vehicle performance while adhering to stringent environmental regulations.

Increasing Focus on Sustainability

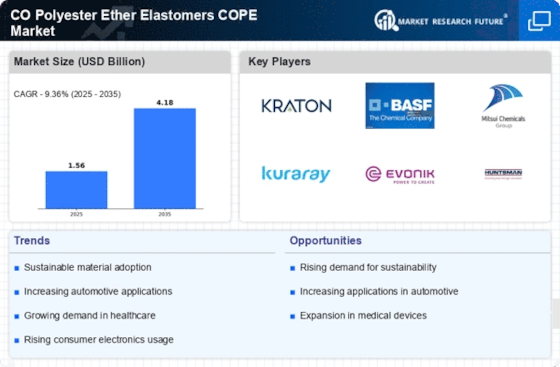

Sustainability initiatives are becoming a cornerstone of the CO Polyester Ether Elastomers COPE Market. As industries worldwide prioritize eco-friendly practices, the demand for sustainable materials is on the rise. COPEs, which can be produced from renewable resources, align well with these sustainability goals. The market is witnessing a shift towards bio-based COPEs, which not only reduce the carbon footprint but also meet the growing consumer demand for environmentally responsible products. This trend is expected to propel the COPE market forward, with projections indicating a potential increase in market share of sustainable materials by 10% over the next five years. Companies that invest in sustainable COPE solutions may gain a competitive edge in this evolving landscape.

Rising Demand for Lightweight Materials

The CO Polyester Ether Elastomers COPE Market is experiencing a notable increase in demand for lightweight materials across various sectors, particularly in automotive and aerospace applications. As manufacturers strive to enhance fuel efficiency and reduce emissions, the adoption of lightweight materials becomes imperative. COPEs, known for their excellent mechanical properties and flexibility, are increasingly favored for components such as seals, gaskets, and flexible hoses. The market for lightweight materials is projected to grow significantly, with estimates suggesting a compound annual growth rate (CAGR) of around 5% over the next few years. This trend indicates a robust opportunity for COPE manufacturers to expand their product offerings and cater to the evolving needs of industries focused on sustainability and performance.

Technological Innovations in Material Science

Technological advancements in material science are significantly influencing the CO Polyester Ether Elastomers COPE Market. Innovations in polymer chemistry and processing techniques are leading to the development of new COPE formulations with enhanced properties. These advancements enable manufacturers to create COPEs that exhibit superior elasticity, durability, and resistance to environmental factors. The introduction of advanced manufacturing processes, such as 3D printing, is also expanding the application scope of COPEs in various industries. As a result, the market is expected to experience a surge in demand for high-performance COPEs, with growth projections suggesting an increase of approximately 7% in the next few years. This technological evolution presents opportunities for companies to differentiate their products and meet the specific needs of diverse applications.