Market Growth Projections

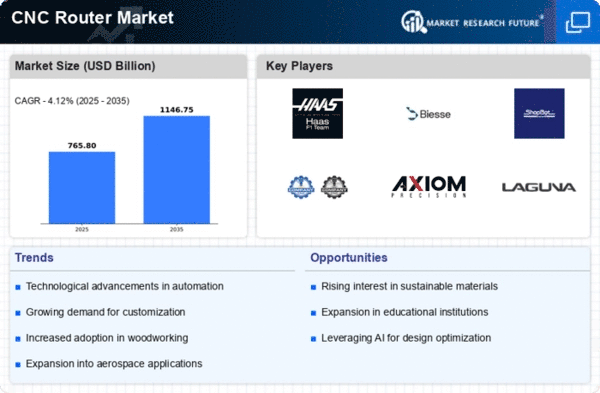

The Global CNC Router Market Industry is projected to experience substantial growth, with estimates indicating a market value of 735.5 USD Billion in 2024 and a potential increase to 1146.7 USD Billion by 2035. This growth trajectory suggests a compound annual growth rate of 4.12% from 2025 to 2035, reflecting the increasing adoption of CNC technology across various sectors. The market's expansion is likely driven by technological advancements, rising demand for customization, and the growth of e-commerce, among other factors. These projections highlight the robust potential of the CNC router market in the coming years.

Technological Advancements

The Global CNC Router Market Industry is experiencing rapid technological advancements, which enhance the capabilities and efficiency of CNC routers. Innovations such as improved software integration, automation, and enhanced cutting tool are driving demand. For instance, the introduction of advanced CAD/CAM software allows for more precise designs and faster production times. As a result, manufacturers can achieve higher productivity levels, which is crucial in a competitive market. This trend is likely to contribute to the market's growth, with projections indicating a market value of 735.5 USD Billion in 2024 and a potential increase to 1146.7 USD Billion by 2035.

Growth of the E-Commerce Sector

The Global CNC Router Market Industry is benefiting from the rapid growth of the e-commerce sector, which has transformed how products are manufactured and delivered. E-commerce platforms require efficient production methods to meet consumer demands for quick turnaround times and high-quality products. CNC routers facilitate this by enabling manufacturers to produce items on-demand, reducing inventory costs and waste. As e-commerce continues to expand, the demand for CNC routers is likely to increase, further propelling the market's growth. This trend aligns with the overall market projections, indicating a steady rise in value over the next decade.

Rising Demand in Various Sectors

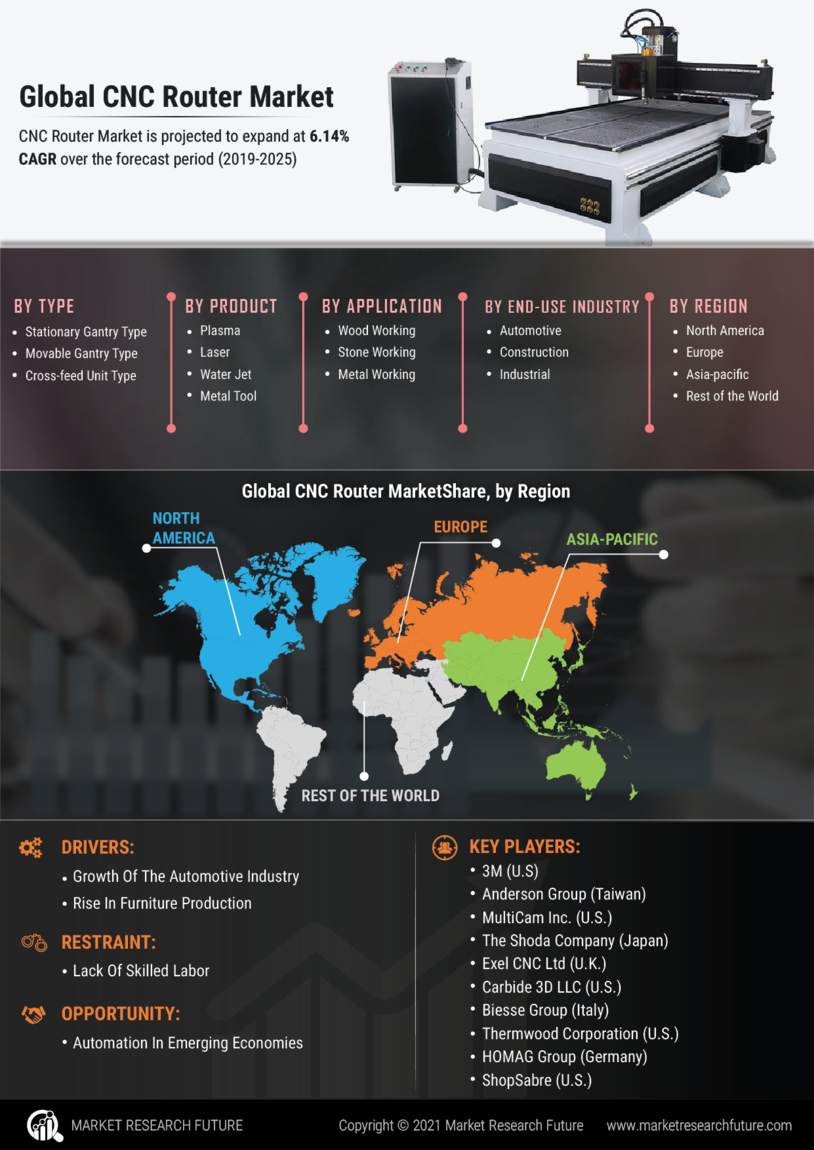

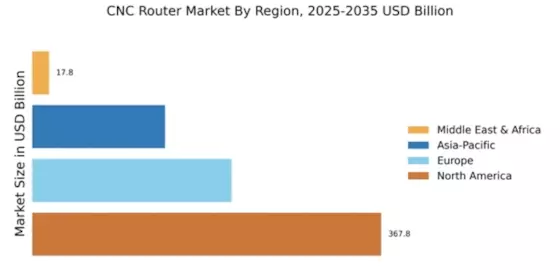

The Global CNC Router Market Industry is witnessing a surge in demand across multiple sectors, including woodworking, metal fabrication, and aerospace. This diversification is driven by the need for precision and efficiency in manufacturing processes. For example, the woodworking tools sector increasingly relies on CNC routers for intricate designs and mass production. The aerospace industry also utilizes CNC technology for creating complex components. This broadening of applications is expected to support a compound annual growth rate of 4.12% from 2025 to 2035, reflecting the growing reliance on CNC routers in various industries.

Customization and Personalization Trends

The Global CNC Router Market Industry is significantly influenced by the rising trends of customization and personalization. Consumers increasingly seek unique products tailored to their specifications, prompting manufacturers to adopt CNC routers for bespoke solutions. This trend is particularly evident in sectors like furniture design and signage, where personalized items command premium prices. As businesses strive to meet these consumer demands, the adoption of CNC technology is likely to increase. This shift towards customization is expected to bolster the market, contributing to its projected growth from 735.5 USD Billion in 2024 to 1146.7 USD Billion by 2035.

Sustainability and Eco-Friendly Practices

The Global CNC Router Market Industry is increasingly aligning with sustainability and eco-friendly practices, which are becoming essential in manufacturing. Companies are adopting CNC routers to minimize waste and optimize material usage, contributing to environmentally responsible production methods. For instance, advanced CNC technology allows for precise cutting, reducing scrap material and energy consumption. As consumers and regulatory bodies emphasize sustainability, manufacturers are likely to invest in CNC routers that support these initiatives. This focus on eco-friendly practices may drive market growth, as businesses seek to enhance their sustainability profiles while maintaining efficiency.