Market Analysis

In-depth Analysis of CNC Machine Market Industry Landscape

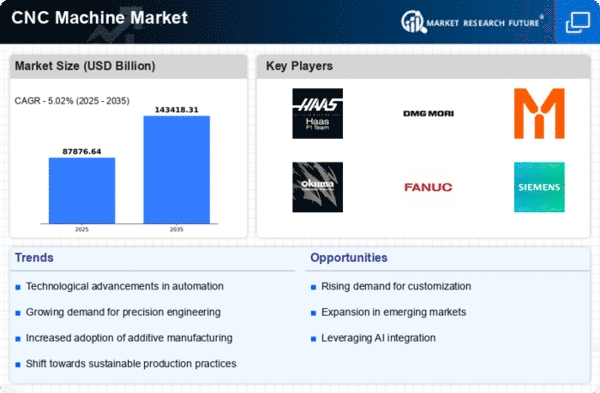

The market dynamics of the CNC (Computer Numerical Control) machine market are multifaceted, influenced by a range of factors that collectively shape supply and demand for these precision machining tools. One of the primary drivers is the growing emphasis on automation and precision in manufacturing processes across various industries. As businesses seek to enhance efficiency and accuracy in production, the demand for CNC machines has witnessed a steady rise. These machines, capable of executing complex machining tasks with high precision, are integral to modern manufacturing operations.

Technological advancements play a pivotal role in the CNC machine market dynamics. Continuous innovations in software, control systems, and tooling technologies contribute to the evolution of CNC machines. Integration of artificial intelligence, data analytics, and the Internet of Things (IoT) into CNC systems is becoming increasingly common, enabling manufacturers to achieve higher levels of automation, productivity, and real-time monitoring. As a result, industries are compelled to upgrade their machining capabilities, fostering the demand for advanced CNC machines.

The aerospace and automotive sectors are significant contributors to the CNC machine market. The need for intricate and precise components in these industries has driven the adoption of CNC machining for manufacturing parts with tight tolerances. Additionally, the medical and electronics sectors, where precision is paramount, further fuel the demand for CNC machines. The versatility of these machines makes them adaptable to various applications, from prototyping to large-scale production.

Global economic factors also impact the CNC machine market dynamics. Economic growth, industrialization, and infrastructure development contribute to increased investments in manufacturing sectors, driving the demand for CNC machines. Conversely, economic downturns may result in reduced capital expenditure by industries, affecting the market negatively.

Market dynamics are also influenced by the competitive landscape within the CNC machine industry. The market comprises established players, regional manufacturers, and emerging entrants, each vying for market share. Competitive strategies, including product innovation, pricing, and strategic partnerships, play a crucial role in shaping the market. Mergers and acquisitions are common, enabling companies to broaden their product portfolios and expand their global footprint.

Government policies and regulations are significant determinants of the CNC machine market dynamics. Policies supporting technological advancements, research and development, and incentives for manufacturing industries can positively impact the market. Conversely, trade restrictions, tariffs, and regulatory hurdles may pose challenges to market players.

The aftermarket segment is another integral aspect of the CNC machine market dynamics. Post-sales services, including maintenance, repair, and parts replacement, contribute substantially to the revenue stream for manufacturers. The availability of efficient aftermarket support is a key factor influencing customers' decisions when choosing CNC machines, as it directly impacts the overall cost of ownership and machine uptime.

Environmental considerations are gaining prominence in the CNC machine market dynamics. Increasing awareness of sustainability and energy efficiency is driving manufacturers to develop eco-friendly CNC machines. This trend is reinforced by government initiatives promoting green manufacturing practices and the adoption of energy-efficient technologies.

The market dynamics of the CNC machine industry are shaped by a confluence of factors, including technological advancements, industry-specific demands, economic conditions, competitive strategies, government policies, aftermarket services, and environmental considerations. As manufacturing processes continue to evolve, the CNC machine market will likely witness ongoing changes, and industry players must remain agile to navigate these dynamic forces successfully.

Leave a Comment