Advancements in Wireless Technology

Advancements in wireless technology are playing a crucial role in shaping the Casting Device Market. The proliferation of Wi-Fi 6 and other high-speed wireless standards has enabled casting devices to deliver superior performance and reliability. In 2025, the market is expected to benefit from these technological improvements, as consumers increasingly demand faster and more stable connections for streaming high-definition content. This shift indicates a growing preference for devices that can support multiple users and devices simultaneously without compromising quality. As a result, manufacturers are investing in research and development to enhance the capabilities of their casting devices, ensuring they meet the evolving needs of tech-savvy consumers. The emphasis on wireless technology not only enhances user experience but also drives competition among manufacturers to innovate and differentiate their products.

Rising Demand for Streaming Services

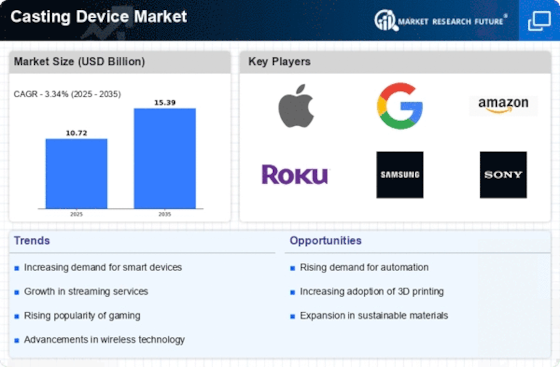

The increasing popularity of streaming services has propelled the Casting Device Market forward. As consumers seek seamless access to content across various platforms, the demand for casting devices has surged. In 2025, the market is projected to reach a valuation of approximately 10 billion USD, driven by the need for high-quality streaming experiences. This trend indicates that consumers are willing to invest in devices that enhance their viewing experiences, thereby stimulating growth in the casting device sector. The rise of original content from streaming platforms further fuels this demand, as users desire to cast their favorite shows and movies onto larger screens. Consequently, manufacturers are focusing on developing innovative casting solutions that cater to this evolving consumer behavior.

Integration of Smart Home Technologies

The integration of smart home technologies is significantly influencing the Casting Device Market. As households increasingly adopt smart devices, the compatibility of casting devices with these technologies becomes paramount. In 2025, it is estimated that over 50% of households will have at least one smart device, creating a substantial market for casting solutions that can seamlessly connect with smart home ecosystems. This trend suggests that consumers are looking for devices that not only cast content but also integrate with their existing smart home setups. Manufacturers are responding by developing casting devices that offer enhanced connectivity features, allowing users to control their devices through voice commands or mobile applications. This integration not only enhances user convenience but also positions casting devices as essential components of modern smart homes.

Consumer Preference for Multi-Device Compatibility

Consumer preference for multi-device compatibility is a key driver in the Casting Device Market. As users own a diverse range of devices, including smartphones, tablets, and laptops, the ability to cast content from multiple sources has become increasingly important. In 2025, it is anticipated that nearly 70% of consumers will prioritize casting devices that offer broad compatibility with various operating systems and applications. This trend indicates a shift towards devices that can seamlessly integrate with users' existing technology ecosystems. Manufacturers are responding by ensuring their casting devices support a wide array of platforms, enhancing user convenience and satisfaction. This focus on compatibility not only meets consumer expectations but also fosters brand loyalty, as users are more likely to choose devices that offer flexibility and ease of use.

Growing Interest in Gaming and Interactive Content

The growing interest in gaming and interactive content is significantly impacting the Casting Device Market. As gaming becomes a more mainstream form of entertainment, the demand for casting devices that can support gaming applications is on the rise. In 2025, it is projected that the gaming segment will account for a substantial share of the casting device market, driven by the increasing popularity of cloud gaming services. This trend suggests that consumers are seeking devices that can provide low-latency streaming and high-quality graphics for an immersive gaming experience. Manufacturers are responding by developing casting devices specifically designed for gaming, incorporating features such as enhanced processing power and compatibility with various gaming platforms. This focus on gaming not only expands the market potential but also attracts a younger demographic that prioritizes interactive entertainment.