Growing Adoption in Emerging Markets

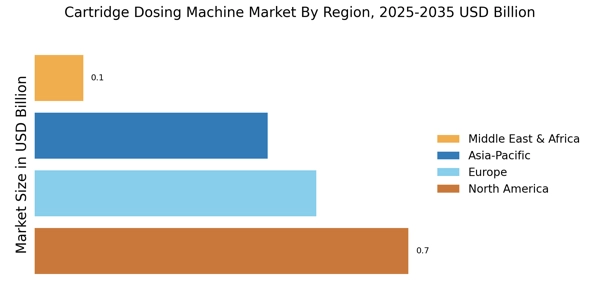

The Cartridge Dosing Machine Market is witnessing a surge in adoption within emerging markets, where industrialization and modernization are rapidly advancing. Countries in Asia and Latin America are increasingly investing in advanced manufacturing technologies, including cartridge dosing machines, to enhance production capabilities. This trend is fueled by the need for efficient and reliable dosing solutions in various sectors, including pharmaceuticals, chemicals, and food processing. Market analysis suggests that the growth rate in these regions could surpass that of more established markets, driven by rising consumer demand and the need for improved manufacturing processes. As a result, the Cartridge Dosing Machine Market is likely to see significant expansion opportunities in these emerging economies.

Regulatory Compliance and Quality Control

The Cartridge Dosing Machine Market is significantly shaped by stringent regulatory requirements across various sectors. Industries such as pharmaceuticals and food production are subject to rigorous quality control standards, necessitating the use of advanced dosing technologies. Cartridge dosing machines offer precise measurement capabilities that help manufacturers comply with these regulations, thereby ensuring product safety and efficacy. The increasing focus on quality assurance is driving the demand for these machines, as companies aim to avoid costly recalls and maintain consumer trust. Data indicates that the market for cartridge dosing machines is expected to expand as businesses prioritize compliance and quality control measures, further solidifying the role of the Cartridge Dosing Machine Market in modern manufacturing.

Sustainability and Eco-Friendly Practices

The Cartridge Dosing Machine Market is increasingly influenced by the global shift towards sustainability and eco-friendly manufacturing practices. Companies are under pressure to reduce their environmental footprint, leading to the adoption of dosing machines that minimize waste and energy consumption. Cartridge dosing machines are designed to optimize material usage, thereby contributing to more sustainable production processes. Recent studies indicate that manufacturers implementing eco-friendly dosing solutions can achieve a reduction in waste by up to 25%. This growing emphasis on sustainability is not only beneficial for the environment but also enhances brand reputation and consumer loyalty. Consequently, the Cartridge Dosing Machine Market is likely to benefit from this trend as businesses seek to align with sustainable practices.

Increased Focus on Automation and Efficiency

The Cartridge Dosing Machine Market is significantly influenced by the growing emphasis on automation and operational efficiency. As industries strive to enhance productivity and reduce labor costs, the integration of automated dosing systems has become increasingly prevalent. These machines not only streamline production processes but also minimize human error, thereby improving overall product quality. Recent statistics suggest that the adoption of automated dosing solutions can lead to efficiency gains of up to 30% in production lines. This trend is particularly evident in sectors such as pharmaceuticals and food processing, where precision and speed are paramount. Consequently, the Cartridge Dosing Machine Market is poised for substantial growth as manufacturers seek to leverage automation to remain competitive.

Rising Demand for Precision in Manufacturing

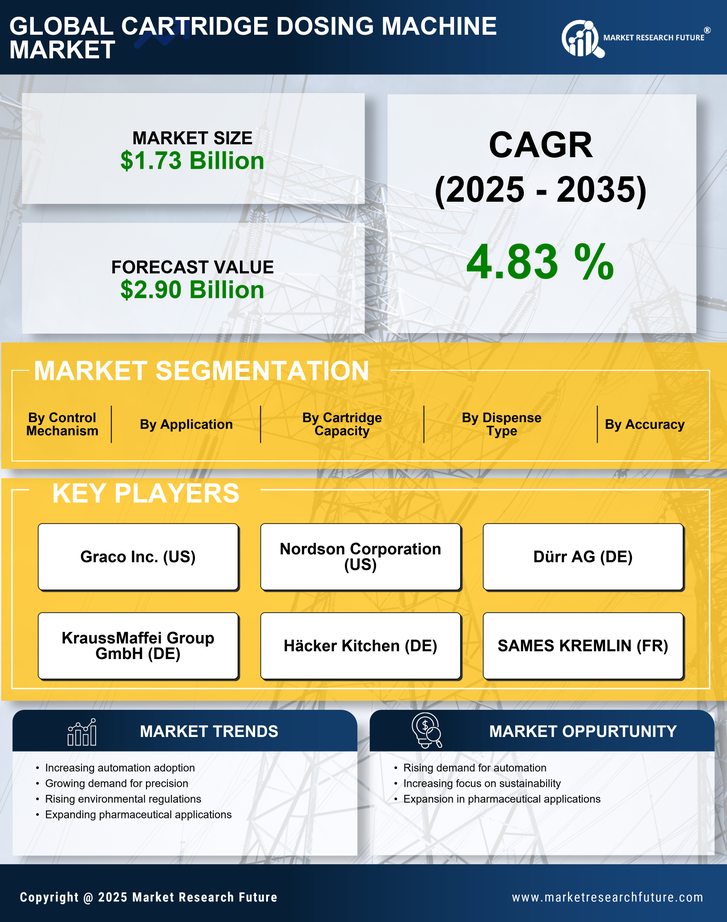

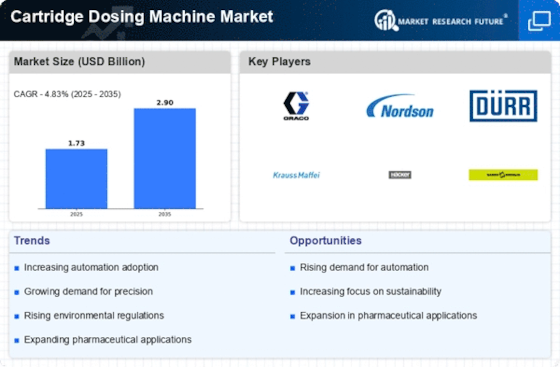

The Cartridge Dosing Machine Market is experiencing a notable increase in demand for precision manufacturing processes. Industries such as pharmaceuticals, food and beverage, and cosmetics are increasingly adopting cartridge dosing machines to ensure accurate and consistent dosing of liquids and powders. This trend is driven by the need for quality assurance and regulatory compliance, as manufacturers seek to minimize waste and enhance product quality. According to recent data, the market for cartridge dosing machines is projected to grow at a compound annual growth rate of approximately 6.5% over the next five years. This growth is indicative of a broader shift towards automation and precision in manufacturing, where the Cartridge Dosing Machine Market plays a pivotal role in meeting these evolving demands.