Expansion of the Electronics Sector

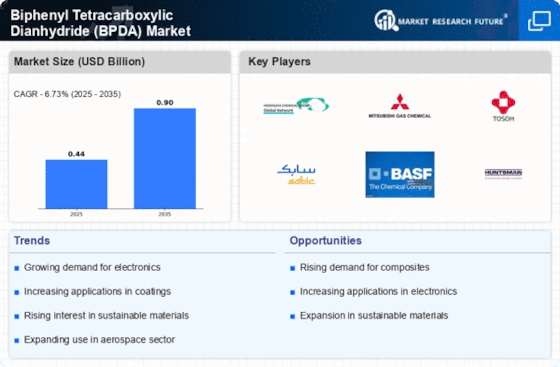

The Biphenyl Tetracarboxylic Dianhydride (BPDA) Market is experiencing growth driven by the expansion of the electronics sector. BPDA is a key component in the production of high-performance polymers used in various electronic applications, including flexible circuits and insulation materials. As consumer electronics continue to evolve, with an emphasis on miniaturization and enhanced performance, the demand for advanced materials is likely to increase. Market data suggests that the electronics industry is on a growth trajectory, which may lead to heightened demand for BPDA. This expansion indicates that the BPDA Market could see significant opportunities as manufacturers seek to innovate and improve electronic products.

Increasing Focus on Renewable Energy

The Biphenyl Tetracarboxylic Dianhydride (BPDA) Market is likely to benefit from the increasing focus on renewable energy sources. BPDA is used in the production of materials for solar panels and wind turbine components, which require high thermal stability and durability. As nations strive to transition towards sustainable energy solutions, the demand for renewable energy technologies is expected to rise. Market forecasts suggest that the renewable energy sector will experience substantial growth, leading to a corresponding increase in the need for BPDA-based materials. This trend indicates that the BPDA Market may play a pivotal role in supporting the development of sustainable energy technologies.

Growth in Electric Vehicle Production

The Biphenyl Tetracarboxylic Dianhydride (BPDA) Market is poised to benefit from the burgeoning electric vehicle (EV) sector. BPDA is integral in the formulation of advanced materials used in EV batteries and components, which require high thermal resistance and electrical insulation. As governments and consumers increasingly prioritize sustainable transportation solutions, the demand for electric vehicles is expected to rise sharply. Market analyses indicate that the EV market could reach unprecedented levels, thereby driving the need for BPDA-based materials. This growth trajectory suggests that the BPDA Market may experience a corresponding increase in demand as manufacturers strive to meet the evolving requirements of the electric vehicle landscape.

Rising Demand in Aerospace Applications

The Biphenyl Tetracarboxylic Dianhydride (BPDA) Market is experiencing a notable surge in demand due to its applications in aerospace materials. BPDA is utilized in the production of high-performance polyimides, which are essential for aerospace components that require exceptional thermal stability and mechanical strength. As the aerospace sector continues to expand, driven by increasing air travel and advancements in aircraft technology, the need for lightweight and durable materials becomes paramount. Reports indicate that the aerospace materials market is projected to grow significantly, with BPDA-based materials playing a crucial role in meeting these demands. This trend suggests that the BPDA Market may witness substantial growth as manufacturers seek to enhance the performance and efficiency of aerospace components.

Advancements in Semiconductor Technology

The Biphenyl Tetracarboxylic Dianhydride (BPDA) Market is significantly influenced by advancements in semiconductor technology. BPDA is utilized in the production of high-performance insulating materials that are essential for semiconductor devices. As the electronics industry continues to innovate, the demand for materials that can withstand high temperatures and provide excellent electrical insulation is critical. The semiconductor market is projected to expand rapidly, driven by the proliferation of smart devices and IoT applications. This growth indicates that the BPDA Market may see increased utilization of BPDA in the manufacturing of next-generation semiconductor components, thereby enhancing overall market dynamics.

.png)