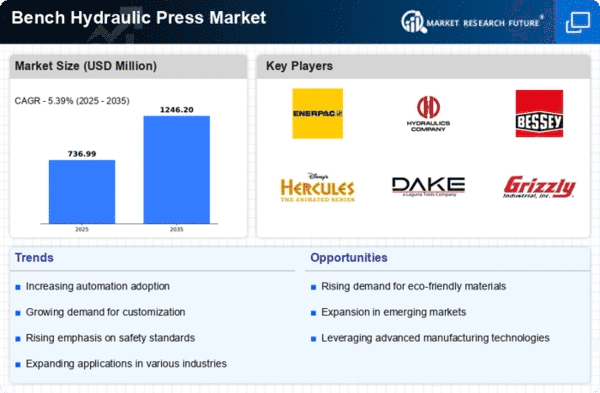

Market Growth Projections

The Global Bench Hydraulic Press Market Industry is poised for substantial growth, with projections indicating a market value of 3.73 USD Billion in 2024 and an anticipated increase to 6.2 USD Billion by 2035. This growth trajectory suggests a compound annual growth rate (CAGR) of 4.72% from 2025 to 2035. Such figures highlight the increasing reliance on hydraulic presses across various sectors, including manufacturing, automotive, and aerospace. The consistent demand for efficient and reliable hydraulic solutions is likely to drive investments and innovations within the industry, shaping its future landscape.

Technological Advancements

Technological advancements play a pivotal role in shaping the Global Bench Hydraulic Press Market Industry. Innovations in hydraulic systems, control mechanisms, and materials have led to the development of more efficient and versatile hydraulic presses. These advancements not only improve performance but also enhance safety features, making them more appealing to end-users. As industries increasingly prioritize automation and precision, the demand for advanced hydraulic presses is expected to rise. This trend is anticipated to contribute to a compound annual growth rate (CAGR) of 4.72% from 2025 to 2035, indicating a robust growth trajectory for the market.

Increased Investment in R&D

Investment in research and development (R&D) is a critical driver of innovation within the Global Bench Hydraulic Press Market Industry. Companies are allocating resources to develop new hydraulic press technologies that enhance efficiency, precision, and safety. This focus on R&D is essential for maintaining competitiveness in a rapidly evolving market. As manufacturers seek to differentiate their products and meet the diverse needs of various industries, the emphasis on innovative hydraulic press solutions is expected to grow. This trend may lead to the introduction of advanced features and capabilities, further stimulating market expansion.

Growing Focus on Sustainability

Sustainability initiatives are becoming increasingly important within the Global Bench Hydraulic Press Market Industry. As companies strive to reduce their environmental impact, there is a growing emphasis on energy-efficient hydraulic presses that minimize energy consumption and waste. Manufacturers are investing in eco-friendly technologies and practices, aligning with global sustainability goals. This shift not only enhances corporate responsibility but also appeals to environmentally conscious consumers. Consequently, the demand for hydraulic presses that meet these sustainability criteria is likely to rise, further propelling market growth in the coming years.

Growing Demand in Manufacturing Sector

The Global Bench Hydraulic Press Market Industry experiences a notable surge in demand driven by the expanding manufacturing sector. As industries increasingly adopt automation and advanced manufacturing techniques, the need for efficient and reliable hydraulic presses becomes paramount. In 2024, the market is projected to reach 3.73 USD Billion, reflecting the industry's reliance on hydraulic presses for tasks such as metal forming, assembly, and material testing. This trend is likely to continue as manufacturers seek to enhance productivity and reduce operational costs, thereby solidifying the hydraulic press's role in modern manufacturing processes.

Rising Adoption in Automotive Industry

The automotive industry significantly influences the Global Bench Hydraulic Press Market Industry, as hydraulic presses are essential for various manufacturing processes, including stamping, molding, and assembly. The increasing production of electric vehicles (EVs) and the need for lightweight materials have further propelled the demand for hydraulic presses. As manufacturers strive for efficiency and sustainability, the integration of hydraulic presses in automotive production lines is likely to expand. This trend is expected to contribute to the market's growth, with projections indicating a market value of 6.2 USD Billion by 2035, underscoring the automotive sector's pivotal role in driving hydraulic press adoption.