Growth in Industrial Automation

The trend towards industrial automation is significantly influencing the Bearing Isolators Market. As manufacturers seek to enhance productivity and reduce labor costs, the integration of automated systems has become prevalent. Bearing isolators play a crucial role in these systems by ensuring the reliability and longevity of machinery. The market for industrial automation is projected to grow at a compound annual growth rate of approximately 9% over the next few years. This growth is expected to drive the demand for bearing isolators, as they are essential for maintaining the performance of automated equipment and reducing maintenance downtime.

Rising Demand for Energy Efficiency

The Bearing Isolators Market is experiencing a notable increase in demand for energy-efficient solutions. Industries are increasingly focusing on reducing energy consumption and operational costs, which has led to a heightened interest in bearing isolators. These components are designed to minimize friction and wear, thereby enhancing the overall efficiency of machinery. According to recent data, energy-efficient systems can reduce energy costs by up to 30%, making bearing isolators a critical component in achieving these savings. As industries strive to meet regulatory standards and sustainability goals, the adoption of bearing isolators is likely to rise, further propelling the market forward.

Increasing Focus on Equipment Longevity

In the Bearing Isolators Market, there is a growing emphasis on extending the lifespan of machinery and equipment. Companies are increasingly recognizing that the longevity of their assets directly impacts operational efficiency and profitability. Bearing isolators contribute to this goal by preventing contamination and reducing wear, which can lead to costly repairs and replacements. Recent studies indicate that implementing bearing isolators can extend equipment life by up to 50%. As industries prioritize maintenance strategies that enhance equipment longevity, the demand for bearing isolators is expected to rise, thereby driving market growth.

Emerging Markets and Economic Development

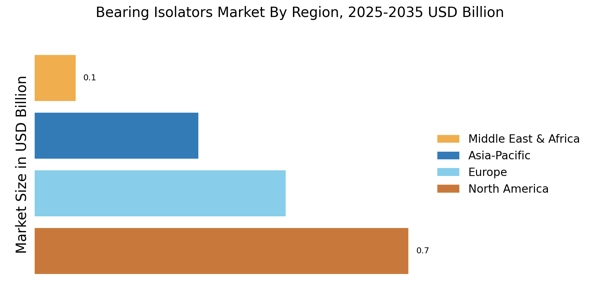

Emerging markets are playing a pivotal role in the expansion of the Bearing Isolators Market. As economies develop, there is a corresponding increase in industrial activities, which drives the demand for reliable machinery components. Countries in Asia and South America are witnessing rapid industrialization, leading to a surge in the need for bearing isolators. The market in these regions is projected to grow significantly, with estimates suggesting a growth rate of around 8% annually. This economic development is likely to create new opportunities for manufacturers and suppliers of bearing isolators, further enhancing market dynamics.

Regulatory Compliance and Safety Standards

The Bearing Isolators Market is also being shaped by stringent regulatory compliance and safety standards. Many industries are required to adhere to specific guidelines that mandate the use of reliable and safe components in their machinery. Bearing isolators help in achieving these compliance requirements by providing effective sealing solutions that prevent contamination and ensure safe operation. As regulations become more rigorous, the demand for bearing isolators is likely to increase, as companies seek to avoid penalties and enhance their safety protocols. This trend is expected to bolster the market as industries invest in compliant technologies.